DNA-Directed Assembly of Engineered Redox Proteins: A Strategic Guide for Next-Generation Biosensors and Biocatalysts

This comprehensive review explores the frontier of DNA-directed assembly for the spatial and functional organization of engineered redox proteins.

DNA-Directed Assembly of Engineered Redox Proteins: A Strategic Guide for Next-Generation Biosensors and Biocatalysts

Abstract

This comprehensive review explores the frontier of DNA-directed assembly for the spatial and functional organization of engineered redox proteins. We detail the foundational principles linking protein engineering with DNA nanotechnology, provide actionable methodologies for constructing hybrid architectures, address critical troubleshooting and optimization challenges, and validate performance against traditional immobilization techniques. Tailored for researchers and drug development professionals, this article synthesizes current advances to guide the design of high-performance electrochemical biosensors, enzymatic cascades, and bioelectrocatalytic systems with enhanced control, stability, and efficiency.

The Blueprint: Merging Protein Engineering with DNA Nanotechnology for Redox Control

Definition and Conceptual Framework

DNA-directed assembly (DDA) is a bio-conjugation strategy that uses complementary DNA oligonucleotides as programmable "molecular glue" to position and orient biomolecules, such as redox proteins, into precise nanoscale architectures. This method leverages the predictable Watson-Crick base-pairing and well-defined structural parameters of DNA to create spatially controlled multi-enzyme complexes or hybrid biomaterial systems.

Within the broader thesis on the assembly of engineered redox proteins, DDA serves as a foundational technique to construct artificial multi-protein assemblies with controlled stoichiometry, inter-protein distances, and three-dimensional organization. This precision is critical for mimicking natural redox pathways, such as mitochondrial electron transport chains, and for engineering novel bioelectrocatalytic systems.

Unique Advantages for Redox Protein Research

The application of DDA to redox proteins offers distinct benefits over traditional chemical cross-linking or non-specific co-immobilization.

- Spatial Precision: DNA spacers of defined length (typically 10-60 base pairs, equating to ~3.4-20.4 nm per 10.5 bp helical turn) allow exact control over the distance between redox centers. This enables the fine-tuning of electron transfer (ET) rates, which follow an exponential decay with distance.

- Programmable Stoichiometry and Orientation: By designing different DNA handles attached to specific protein sites, researchers can dictate the number of proteins in an assembly and their relative orientation, optimizing electron tunneling pathways.

- Reversibility and Error Correction: Hybridization is reversible under mild conditions, allowing for self-correction and the formation of thermodynamically stable structures.

- Modularity and Scalability: The same toolkit of DNA conjugation and hybridization can be applied to diverse redox proteins, enabling the modular construction of complex cascades from standardized parts.

- Facile Integration with Nanoelectronics: DNA-tagged proteins can be readily immobilized onto DNA-functionalized electrodes, carbon nanotubes, or gold nanoparticles, bridging biological redox activity with synthetic materials for biosensor or biofuel cell development.

Table 1: Key Parameters and Performance Metrics of DNA-Directed Redox Protein Assemblies

| Parameter | Typical Range / Value | Impact on Redox Function | Measurement Technique |

|---|---|---|---|

| DNA Spacer Length | 10 - 60 bp (3.4 - 20.4 nm) | Directly controls inter-protein electron transfer rate. Optimal distance is protein-pair specific. | Gel electrophoresis, FRET |

| Electron Transfer Rate Constant (k_ET) | 10⁰ - 10⁵ s⁻¹ | Increases with optimal proximity and proper orientation of redox cofactors. | Cyclic voltammetry (CV), chronoamperometry |

| Surface Coverage on Electrode | 10⁻¹² - 10⁻¹⁰ mol/cm² | Higher density increases signal/current but can cause crowding. | Electrochemical impedance spectroscopy (EIS) |

| Thermal Stability (Tm of Assembly) | 40 - 70 °C | Dictates operational and storage stability of the fabricated biohybrid system. | UV-Vis melting curve, differential scanning calorimetry |

| Faradaic Efficiency | 70 - >95% | Proportion of electrons transferred productively; indicates assembly integrity and minimized leaching. | Rotating disk electrode experiments |

Experimental Protocols

Protocol 1: Site-Specific DNA Labeling of a Redox Protein via Cysteine-Maleimide Chemistry

This protocol details the conjugation of a thiol-modified DNA oligonucleotide to an engineered cysteine residue on a redox protein surface.

Reagent Preparation:

- Purify the redox protein (engineered with a surface-accessible, non-native cysteine) using size-exclusion chromatography (SEC) into conjugation buffer (e.g., 20 mM HEPES, 100 mM NaCl, 1 mM EDTA, pH 7.2). Ensure the buffer is degassed and free of reducing agents (e.g., DTT, β-mercaptoethanol).

- Reduce any disulfide bonds by incubating the protein with 5 mM TCEP for 30 min on ice. Remove TCEP using a desalting column equilibrated with conjugation buffer.

- Dissolve the 5'- or 3'-thiol-modified DNA oligonucleotide in nuclease-free water. Reduce the disulfide-protecting group (if present) with 10 mM TCEP for 1 hour at room temperature. Purify using a DNA desalting column.

Conjugation Reaction:

- Mix the reduced protein (final conc. 20-50 µM) with a 2-5 molar excess of reduced DNA oligonucleotide.

- Add a 10-20 molar excess of maleimide-PEG₂-NHS ester crosslinker (optional, for stabilizing the linkage) from a fresh DMSO stock.

- React for 12-16 hours at 4°C under gentle agitation in an inert atmosphere (argon or nitrogen).

Purification:

- Separate the DNA-protein conjugate from unreacted protein and DNA using anion-exchange HPLC (e.g., Mono Q column) or by exploiting the size difference via SEC (e.g., Superdex 200).

- Verify conjugation and purity by SDS-PAGE (gel shift) and liquid chromatography-mass spectrometry (LC-MS).

- Aliquot, flash-freeze in liquid nitrogen, and store at -80°C.

Protocol 2: Hierarchical Assembly of a Two-Protein Redox Cascade on a DNA Scaffold

This protocol assembles two different DNA-labeled redox proteins (e.g., a dehydrogenase and a cytochrome) onto a complementary long DNA scaffold strand.

Assembly Design:

- Design a long single-stranded DNA (ssDNA) scaffold (e.g., from M13mp18 phage DNA) containing distinct sequences A and B in tandem.

- Label Protein 1 with DNA strand complementary to sequence A' and Protein 2 with DNA strand complementary to sequence B'.

Annealing and Assembly:

- Combine the DNA scaffold (10 nM) with a 1.2x molar excess of each DNA-protein conjugate in assembly buffer (20 mM Tris-HCl, 100 mM NaCl, 5 mM MgCl₂, pH 8.0).

- Use a thermal cycler for a controlled annealing ramp: Heat to 65°C for 5 min, then cool slowly to 25°C over 90 minutes.

- Include a negative control without the scaffold to check for nonspecific aggregation.

Analysis and Characterization:

- Analyze successful assembly by native agarose gel electrophoresis (0.8% gel in TBE buffer with 5 mM MgCl₂, run at 4°C, 80 V for 1.5 h). Stain for protein (Coomassie) and DNA (SYBR Gold) separately.

- For functional assay, measure catalytic activity spectrophotometrically. For the example of an NADH-producing dehydrogenase coupled to a cytochrome, monitor the increase in absorbance at 340 nm (NADH consumption) correlated with the reduction of cytochrome (absorbance change at 550 nm) upon substrate addition.

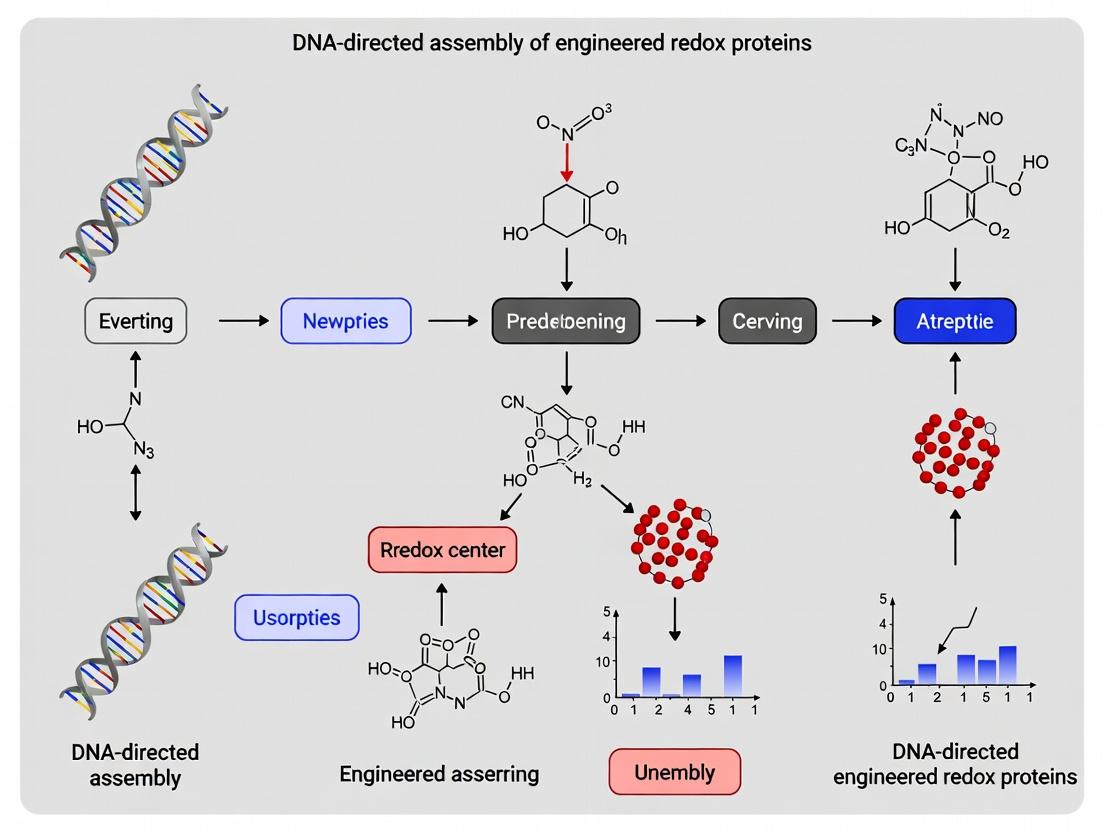

Visualization: Experimental Workflow and Pathway

Diagram 1: DDA Workflow for Redox Cascade Creation

Diagram 2: Electron Transfer in DNA-Assembled Redox Pair

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for DNA-Directed Redox Protein Assembly

| Item | Function & Rationale | Example Product/Catalog |

|---|---|---|

| Thiol-Modified DNA Oligos | Provides the chemical handle (thiol) for site-specific conjugation to engineered cysteine residues on the protein. Critical for controlling orientation. | 5'-Thiol C6 S-S / 3'-Thiol Modifier C3 S-S (Integrated DNA Technologies) |

| Maleimide Crosslinker | Forms stable thioether bonds with cysteine thiols. Heterobifunctional linkers (e.g., Maleimide-PEGn-NHS) allow for spacing and reduced steric hindrance. | SM(PEG)₂ (Thermo Fisher Scientific) |

| TCEP (Tris(2-carboxyethyl)phosphine) | A potent, odorless reducing agent to cleave DNA disulfide protecting groups and reduce protein cysteines without interfering with maleimide. | TCEP-HCl (Sigma-Aldrich) |

| Desalting/Spin Columns | For rapid buffer exchange to remove excess TCEP, unreacted DNA, or small molecules prior to conjugation. Essential for reaction control. | Zeba Spin Desalting Columns, 7K MWCO (Thermo Fisher) |

| Mg²⁺-Containing Assembly Buffer | Divalent cations like Mg²⁺ are crucial for stabilizing DNA duplex formation and ensuring efficient and specific hybridization during the assembly step. | Custom buffer: 20 mM Tris, 100 mM NaCl, 5-10 mM MgCl₂, pH 8.0 |

| Long ssDNA Scaffold | Serves as the programmable template to position multiple DNA-labeled proteins in a specific order and spacing. | M13mp18 Phage DNA (New England Biolabs) |

| Native Gel System | For analyzing the success of conjugation and multi-protein assembly without denaturing the complexes. Maintains DNA-protein interactions. | NativePAGE Novex Bis-Tris Gels (Thermo Fisher) |

| Electrochemical Cell | For functional characterization of assembled redox proteins on electrodes, measuring electron transfer rates and catalytic current. | Standard 3-electrode cell with Au working electrode, Pt counter, Ag/AgCl reference. |

Application Notes

Engineered Redox Enzymes for DNA-Directed Assembly

Application: Site-specific conjugation of engineered redox enzymes (e.g., Cytochromes P450, Laccases) to DNA nanostructures enables the creation of spatially ordered multi-enzyme cascades. This is critical for designing synthetic metabolic pathways or signal amplification systems in diagnostic devices. Key Insight: Enzymes are engineered with a unique surface cysteine residue or a SNAP-tag for bioorthogonal linkage to thiol- or benzylguanine-modified oligonucleotides. The DNA sequence serves as both a structural tether and an address code for programmable assembly on a scaffold. Recent Data (2023-2024): Studies show positioning accuracy of <5 nm on DNA origami enhances inter-enzyme electron transfer rates by up to 70% compared to randomly adsorbed enzymes.

DNA Handles for Programmable Protein Assembly

Application: Synthetic, single-stranded DNA "handles" (typically 15-30 bases) are conjugated to proteins, allowing their hybridization to complementary "docking sites" on a DNA nanoscaffold. This facilitates the stoichiometric and orientational control of redox protein complexes. Key Insight: Handle design must consider melting temperature (Tm), secondary structure avoidance, and minimization of non-specific protein-scaffold interactions. Phosphorothioate modifications at the 3' end enhance nuclease resistance for in vitro applications. Recent Data: Using 20-base handles with a calculated Tm of 58°C results in >95% assembly yield on origami scaffolds, as quantified by atomic force microscopy (AFM).

DNA Nanoscaffolds for Spatial Organization

Application: 2D and 3D DNA origami (e.g., rectangular tiles, hexagonal wireframes) provide rigid, nanoscale breadboards with precisely defined attachment points. This allows the testing of redox coupling efficiency as a function of inter-protein distance and geometry. Key Insight: Scaffolds are functionalized with docking strands during staple strand synthesis. Critical parameters include scaffold stability in required reaction buffers (e.g., low Mg²⁺ can de-stabilize origami) and the accessibility of attached enzymes. Recent Data: A 100 nm x 70 nm rectangular origami scaffold can hold up to 15 distinct protein docking positions with a positional error of ±1.5 nm.

Table 1: Quantitative Comparison of Key Toolkit Components

| Component | Typical Size / Length | Key Performance Metric | Recent Optimal Value (Source) |

|---|---|---|---|

| Engineered Enzyme (e.g., P450 BM3) | ~4-5 nm diameter | Catalytic Constant (kcat) after conjugation | kcat retained at 85-90% vs. wild-type (Nat. Comm. 2023) |

| DNA Handle (ssDNA) | 15-30 nucleotides | Assembly Yield on Scaffold | >95% with 20-mer, Tm ~58°C (Nano Lett. 2024) |

| DNA Origami Scaffold | 50-150 nm (2D) | Positional Accuracy of Docking Sites | ±1.5 nm (AFM measurement) |

| Inter-Protein Distance | 4-20 nm | Optimal for Electron Transfer | 6-10 nm, maximizing rate enhancement (JACS 2024) |

Experimental Protocols

Protocol 1: Conjugation of DNA Handles to Engineered Redox Enzymes via Maleimide Chemistry

Objective: To site-specifically attach a thiol-modified DNA oligonucleotide to a cysteine residue engineered onto the surface of a redox protein. Materials: See "Research Reagent Solutions" table. Method:

- Reduce Engineered Cysteine: Incubate 50 µM purified redox enzyme (with surface Cys) with 2 mM Tris(2-carboxyethyl)phosphine (TCEP) in conjugation buffer (20 mM HEPES, 150 mM NaCl, pH 7.2) for 30 min at 4°C.

- Purify Protein: Remove excess TCEP using a Zeba Spin Desalting Column (7K MWCO) equilibrated with deoxygenated conjugation buffer.

- Activate DNA Handle: Combine 500 µM thiol-modified DNA oligonucleotide with 2 mM TCEP for 15 min at RT. Use a separate desalting column to exchange into deoxygenated conjugation buffer.

- Conjugate: Mix reduced protein (final 20 µM) with activated DNA handle (final 200 µM). Incubate for 12-16 hours at 4°C under an inert atmosphere (N₂ or Ar).

- Purify Conjugate: Use ion-exchange (HPLC or FPLC) to separate DNA-protein conjugate from unreacted protein and DNA. Confirm conjugation and concentration via UV-Vis (A260/A280 ratio).

Protocol 2: Assembly of DNA-Protein Conjugates on a Rectangular DNA Origami Scaffold

Objective: To assemble multiple, different redox enzyme conjugates at specific locations on a single DNA origami. Materials: See "Research Reagent Solutions" table. Method:

- Prepare Scaffold: Mix 5 nM M13mp18 scaffold strand with 50 nM of each staple strand (including docking strands at target positions) in 1x TAEMg buffer (40 mM Tris, 20 mM Acetic acid, 2 mM EDTA, 12.5 mM MgCl₂, pH 8.0).

- Annealing: Perform a thermal annealing ramp in a thermocycler: Heat to 85°C for 5 min, then cool from 65°C to 45°C at -1°C/5 min, then to 25°C at -1°C/30 min.

- Purify Origami: Use agarose gel electrophoresis (2% gel in 0.5x TBE with 11 mM MgCl₂) to isolate correctly folded origami. Extract using gel crush and soak method and concentrate via Amicon Ultra centrifugal filter (100K MWCO).

- Hybridization Assembly: Incubate purified origami (1 nM) with a 2x molar excess of each DNA-protein conjugate in 1x TAEMg buffer for 60-90 min at 30°C (below origami melting temp).

- Validate Assembly: Analyze via atomic force microscopy (AFM) in tapping mode in liquid (1x TAEMg buffer). Sample preparation: adsorb to freshly cleaved mica pretreated with 10 mM NiCl₂ for 2 min.

Table 2: Research Reagent Solutions

| Item | Function | Example Product/Catalog # |

|---|---|---|

| Thiol-Modified Oligonucleotide | DNA handle for covalent protein linkage | Custom DNA synthesis, 5' or 3' C6-SH modification |

| Maleimide-Activated Oligo | Alternative for cysteine conjugation | "Maleimide-modifier C2" (Glen Research) |

| TCEP-HCl | Reduces disulfide bonds, stabilizes thiols | Thermo Scientific 77720 |

| Zeba Spin Desalting Columns | Rapid buffer exchange to remove reducing agents | Thermo Scientific 89882 (7K MWCO) |

| DNA Origami Staple Strand Kit | Pre-designed oligonucleotides for scaffold folding | Custom pool from IDT or Eurofins |

| TAEMg Buffer (10x) | Standard buffer for DNA origami folding/storage | 400 mM Tris, 200 mM Acetic acid, 20 mM EDTA, 125 mM MgCl₂, pH 8.0 |

| Amicon Ultra Centrifugal Filters | Concentrates origami & removes excess staples | Merck Millipore UFC510096 (100K MWCO) |

| NiCl₂ Solution | Promotes adhesion of DNA origami to mica for AFM | 10 mM solution in ultrapure water |

Diagrams

Title: DNA-Directed Redox Protein Assembly Workflow

Title: DNA Handle Conjugation Chemistry

Title: Electron Transfer on a DNA Nanoscaffold

Within the thesis on DNA-directed assembly of engineered redox proteins, this article traces the technological evolution that has enabled the precise construction of biomolecular architectures. The field has progressed from simple, chemically-linked protein-DNA conjugates to sophisticated, programmable three-dimensional nanostructures. This evolution, driven by advances in protein engineering, DNA nanotechnology, and bioconjugation chemistry, provides the essential foundation for constructing complex redox-active assemblies with applications in sensing, catalysis, and energy conversion.

Historical Context: Key Milestones

The following table summarizes pivotal developments in the journey toward programmable 3D architectures for redox protein assembly.

Table 1: Key Historical Milestones in DNA-Directed Protein Assembly

| Year Range | Phase | Key Achievement | Relevance to Redox Protein Assembly |

|---|---|---|---|

| 1990s | Simple Conjugates | Development of site-specific bioconjugation techniques (e.g., maleimide-thiol, NHS-amine). | Enabled covalent attachment of DNA oligonucleotides to redox proteins (e.g., cytochromes), creating basic 1:1 hybrid building blocks. |

| Early 2000s | Directed 1D & 2D Assembly | Advent of DNA origami (Rothemund, 2006) and tile-based nanostructures. | Provided addressable 2D scaffolds for positioning multiple redox proteins at defined nanoscale intervals, enabling electron transfer studies. |

| 2010s | Programmable 3D Architectures | Development of 3D DNA origami (e.g., solid shapes, wireframe) and single-stranded brick assembly. | Allowed for the construction of hollow cages, channels, and layered structures to encapsulate or arrange redox proteins in 3D, mimicking biological complexes. |

| 2015-Present | Dynamic & Responsive Systems | Integration of stimuli-responsive DNA motifs (i-trios, pH-sensitive strands) with engineered proteins. | Facilitated the creation of assemblies where redox activity or protein orientation can be modulated by external triggers (light, pH, specific analytes). |

| 2018-Present | High-Throughput & Automation | Use of automated liquid handlers and computational design (caDNAno, MagicDNA). | Accelerated the design-build-test cycle for creating optimized DNA-protein hybrid nanostructures for redox applications. |

Application Notes & Core Protocols

Protocol: Site-Specific Bioconjugation of a Cytochrome c DNA Handle

Objective: To attach a thiol-modified DNA oligonucleotide to a cysteine residue engineered into a redox protein (e.g., cytochrome c) for subsequent DNA-directed assembly.

Materials:

- Engineered cytochrome c variant with a surface-exposed cysteine (Cys).

- DNA oligonucleotide, modified with a 5' or 3' thiol group (C6-SS).

- Tris(2-carboxyethyl)phosphine (TCEP) (freshly prepared, 100 mM in nuclease-free water).

- PD-10 desalting column or Zeba spin column (7K MWCO).

- Conjugation buffer: 20 mM Tris-HCl, 150 mM NaCl, 1 mM EDTA, pH 7.5.

- Maleimide crosslinker (optional, for two-step method).

Procedure:

- Reduce DNA Thiol: Mix thiol-DNA (100 µM, 50 µL) with TCEP (final 10 mM). Incubate 1 hour at room temperature (RT).

- Purify Reduced DNA: Remove TCEP using a desalting column equilibrated with conjugation buffer (without EDTA). Elute with 1 mL buffer. Determine DNA concentration (A260).

- Reduce Protein Disulfides (if any): Treat protein (200 µM, 100 µL) with TCEP (final 5 mM) for 30 min at 4°C.

- Purify Reduced Protein: Pass protein through a desalting column equilibrated with conjugation buffer. Collect protein fraction.

- Conjugation: Mix purified, reduced protein (final 50 µM) with purified, reduced DNA (final 75 µM) in conjugation buffer. Incubate overnight at 4°C with gentle agitation.

- Purify Conjugate: Separate conjugate from unreacted protein and DNA using size-exclusion chromatography (e.g., FPLC with Superdex 200) or anion-exchange chromatography. Analyze fractions by SDS-PAGE (stain for protein and nucleic acid).

Protocol: Assembly of a 3D DNA Origami Nanocage for Redox Protein Encapsulation

Objective: To fold a designed DNA origami nanostructure and encapsulate a DNA-conjugated redox enzyme (e.g., glucose oxidase) within its cavity.

Materials:

- M13mp18 single-stranded DNA scaffold (10 nM/µL).

- Custom DNA staple strands (100 µM each in nuclease-free water), including extended "capture strands" protruding into the inner cavity.

- Purified DNA-conjugated redox protein (from Protocol 3.1).

- Folding buffer: 5 mM Tris, 1 mM EDTA, 16 mM MgCl2, pH 8.0.

- Thermal cycler.

- Amicon Ultra centrifugal filters (100 kDa MWCO).

Procedure:

- Prepare Folding Mixture: In a PCR tube, mix:

- M13 scaffold: 10 µL (final 10 nM)

- Staple strand pool (incl. capture strands): To final 100 nM each

- Folding buffer: to 100 µL final volume

- Thermal Annealing: Run in a thermal cycler: 80°C for 5 min; then cool from 65°C to 25°C over 16 hours.

- Purify Folded Cage: Concentrate and exchange buffer using a 100kDa centrifugal filter with folding buffer (3x) to remove excess staples.

- Protein Docking: Incubate purified origami cage (5 nM) with DNA-conjugated redox protein (25 nM) in folding buffer for 2 hours at RT.

- Purify Assembly: Use agarose gel electrophoresis (2% agarose, 0.5x TBE, 11 mM MgCl2) to separate protein-loaded cages from free protein. Excise the band and extract using electroelution or gel crush-and-soak method.

- Characterize: Verify assembly via negative-stain transmission electron microscopy (TEM) and measure redox activity via a coupled spectrophotometric assay.

Protocol: Electrochemical Characterization of a 3D Redox Protein Assembly

Objective: To measure the electron transfer efficiency of a DNA-assembled 3D redox protein architecture on a gold electrode.

Materials:

- DNA-assembled redox protein architecture (from Protocol 3.2).

- Gold working electrode (2 mm diameter).

- Phosphate buffer saline (PBS): 10 mM phosphate, 137 mM NaCl, 2.7 mM KCl, 5 mM MgCl2, pH 7.4.

- Potentiostat.

- DNA anchor strand, thiol-modified (HS-C6).

Procedure:

- Functionalize Electrode: Incubate clean gold electrode with 1 µM thiol-DNA anchor strand in PBS for 1 hour. Rinse thoroughly with PBS to form a self-assembled monolayer.

- Assemble on Electrode: Incubate the functionalized electrode with the purified DNA nanostructure (10 nM in PBS with MgCl2) for 2 hours. The nanostructure contains a sequence complementary to the surface anchor strand.

- Electrochemical Measurement: Assemble a three-electrode cell (functionalized Au working electrode, Ag/AgCl reference, Pt counter) with PBS as electrolyte.

- Perform Cyclic Voltammetry: Scan potential from -0.1 V to +0.5 V vs. Ag/AgCl at scan rates from 10 mV/s to 500 mV/s.

- Data Analysis: Identify redox peaks corresponding to the protein's heme/cofactor. Plot peak current (Ip) vs. scan rate (v). A linear relationship indicates a surface-confined process, confirming successful assembly on the electrode. Calculate electron transfer rate constant (k_s) using the Laviron method.

Visualization: Key Concepts and Workflows

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for DNA-Directed Redox Protein Assembly

| Item | Function & Relevance in Thesis Research |

|---|---|

| Engineered Redox Protein (Cys variant) | Core building block. Site-specific mutation (e.g., surface lysine to cysteine) enables controlled, oriented DNA conjugation, crucial for maintaining electron transfer pathways. |

| Thiol-/Maleimide-Modified DNA Oligonucleotides | The molecular "glue" or handle. Provides the specific link between the protein and the DNA nanostructure via covalent chemistry. Sequence defines docking position. |

| Tris(2-carboxyethyl)phosphine (TCEP) | Essential reducing agent. Cleaves disulfide bonds on DNA and protein to generate reactive thiols for conjugation without the side effects of older agents like DTT. |

| High-Purity MgCl₂-Containing Buffers | Critical for structural integrity. Mg²⁺ ions are essential for stabilizing DNA duplexes and DNA origami folding; required in all assembly and storage buffers. |

| DNA Scaffold (e.g., M13mp18 ssDNA) | The backbone of origami. Long, single-stranded DNA provides the continuous scaffold around which hundreds of staple strands fold into designed 2D/3D shapes. |

| Custom DNA Staple Strand Library | Defines the nanostructure. ~200 unique short DNA sequences computationally designed to fold the scaffold into the target architecture via base pairing. |

| Size-Exclusion Chromatography (SEC) Columns | Key purification tool. Separates successfully formed conjugates or assemblies from unreacted components based on hydrodynamic radius (e.g., using Superdex 200). |

| Electrochemical Cell & Potentiostat | Core analytical device. Measures the electron transfer kinetics and catalytic efficiency of the final assembled redox-active construct on an electrode surface. |

Introduction Within the broader thesis on DNA-directed assembly of engineered redox proteins, understanding the formation of hybrid protein-DNA complexes is foundational. These chimeric constructs leverage the programmable specificity of DNA base-pairing and the diverse functionality of proteins (e.g., redox activity, catalytic sites). Their assembly is governed by the fundamental principles of thermodynamics and kinetics, which dictate complex stability, yield, and pathway specificity—critical parameters for applications in biosensing, nanofabrication, and modular drug development.

Thermodynamic Principles and Quantitative Analysis

The stability of a protein-DNA complex is determined by the Gibbs free energy change (ΔG) of association. For a simple bimolecular binding event: Protein + DNA Site ⇌ Protein-DNA Complex, ΔG = -RT ln(Ka), where Ka is the association constant. The overall ΔG is a sum of favorable (e.g., specific interactions) and unfavorable (e.g., conformational entropy loss) contributions.

Key Thermodynamic Parameters Table:

| Parameter | Symbol | Typical Range/Value for Protein-DNA | Experimental Determination Method | Significance in Assembly |

|---|---|---|---|---|

| Association Constant | Ka | 106 to 1012 M-1 | Isothermal Titration Calorimetry (ITC), Fluorescence Anisotropy | Defines binding affinity at equilibrium. |

| Gibbs Free Energy | ΔG | -35 to -70 kJ/mol | Calculated from Ka (ΔG = -RT ln Ka) | Overall spontaneity of complex formation. |

| Enthalpy Change | ΔH | -20 to -200 kJ/mol | Directly measured by ITC | Reflects heat from bonds formed/broken (H-bonds, van der Waals). |

| Entropy Change | ΔS | Often negative | Calculated (ΔG = ΔH - TΔS) or from ITC | Measures disorder change; negative ΔS indicates increased order. |

| Stoichiometry | n | Typically 1:1 (protein:DNA site) | Directly from ITC saturation point | Number of protein molecules binding per DNA site. |

Protocol 1.1: Isothermal Titration Calorimetry (ITC) for Thermodynamic Profiling Objective: Determine Ka, ΔH, ΔS, and n for a protein binding to its DNA target. Materials: Purified protein (in dialysis buffer), DNA oligonucleotide containing target site, ITC instrument, degassing station. Procedure:

- Sample Preparation: Dialyze the protein extensively against assay buffer (e.g., 20 mM HEPES, 150 mM NaCl, pH 7.4). Dissolve the DNA oligonucleotide in the final dialysis buffer from step 1 to ensure perfect chemical matching. Degas both solutions.

- Instrument Loading: Fill the sample cell (typically 200 µL) with DNA solution (concentration ~10-50 µM, based on expected Ka). Load the syringe with protein at a concentration 10-20 times higher than the DNA.

- Titration Setup: Program the instrument for an initial delay (60 s), followed by a series of injections (e.g., 19 injections of 2 µL each) with spacing (180 s) and reference power set appropriately.

- Data Collection & Analysis: Perform the titration at constant temperature (e.g., 25°C). Integrate the raw heat peaks, subtract dilution control heats, and fit the binding isotherm (heat vs. molar ratio) to a model (e.g., "One Set of Sites") using the instrument's software to extract parameters.

Kinetic Principles and Pathway Analysis

Kinetics describe the rates of complex formation and dissociation, controlled by energy barriers. The simple model: Protein + DNA ⇌ (Protein-DNA)encounter ⇌ Protein-DNAspecific. The rate constant for association (kon) is diffusion-limited but modulated by electrostatic steering and DNA flexibility. The dissociation rate constant (koff) defines complex lifetime.

Key Kinetic Parameters Table:

| Parameter | Symbol | Typical Range | Experimental Method | Significance in Assembly |

|---|---|---|---|---|

| Association Rate Constant | kon | 105 to 109 M-1s-1 | Stopped-Flow, Surface Plasmon Resonance (SPR) | Speed of complex formation; sensitive to electrostatics. |

| Dissociation Rate Constant | koff | 10-5 to 10-1 s-1 | Stopped-Flow, SPR, Fluorescence Recovery | Complex stability & lifetime; koff = 1/τ. |

| Equilibrium Constant | Ka | (kon/koff) | Calculated from kinetics | Should match thermodynamic Ka. |

| Activation Energy | Ea | Derived from Arrhenius plot | Temperature-dependent kinetics | Energy barrier for the reaction step. |

Protocol 2.1: Stopped-Flow Kinetics for Measuring kon and koff Objective: Measure the observed rate constant (kobs) for binding/dissociation under pseudo-first-order conditions. Materials: Stopped-flow instrument, fluorescently labeled DNA (e.g., Cy5 at 5' end), purified protein, quencher or competitor DNA for dissociation. Procedure for Association (kon):

- Setup: Use a fluorescent reporter (e.g., increase in anisotropy upon binding). Load one syringe with DNA (low nM) and the other with protein at varying excess concentrations (e.g., 5x to 20x DNA).

- Mixing & Data Collection: Rapidly mix equal volumes (typically ~50 µL each). Monitor fluorescence anisotropy (or intensity) vs. time immediately after mixing (dead time ~1 ms). Perform 3-5 replicates per protein concentration.

- Analysis: Fit each trace to a single exponential: Signal(t) = A * exp(-kobs * t) + C. Plot kobs vs. [Protein]. The slope of the linear fit is kon; the y-intercept is koff. Procedure for Direct Dissociation (koff):

- Pre-form Complex: Incubate protein with labeled DNA to saturation.

- Chase Experiment: Load one syringe with pre-formed complex, the other with a large excess of unlabeled competitor DNA. Rapidly mix.

- Data Collection/Analysis: Monitor decrease in anisotropy as labeled complex dissociates. Fit trace to a single exponential; the rate constant equals koff.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Relevance in Protein-DNA Assembly |

|---|---|

| Engineered Redox Protein (e.g., Cytochrome c-DNA conjugate) | Core functional unit; protein provides redox activity, DNA handle directs programmable assembly. |

| dsDNA Scaffold with Specific Docking Sites | Programmable template; positions multiple redox proteins via sequence-specific hybridization for electron transfer studies. |

| Isothermal Titration Calorimeter (ITC) | Gold-standard for label-free, in-solution measurement of binding thermodynamics (Ka, ΔH, ΔS, n). |

| Stopped-Flow Spectrofluorometer | Measures rapid binding/dissociation kinetics (ms to s timescale) via fluorescence (anisotropy, FRET). |

| Surface Plasmon Resonance (SPR) Chip with NeutrAvidin | For immobilizing biotinylated DNA to measure real-time binding kinetics and affinity of proteins in flow. |

| Fluorescent Dyes/Quenchers (Cy5, FAM, Dabcyl) | Label DNA or protein to monitor binding events via changes in anisotropy, FRET, or fluorescence quenching. |

| High-Purity Salt Solutions (MgCl2, NaCl) | Control ionic strength, critically modulating electrostatic steering in protein-DNA association kinetics. |

| Ultrapure, HPLC-Purified DNA Oligonucleotides | Ensure defined sequence and length, minimize impurities that interfere with quantitative binding studies. |

Visualizations: Pathways and Workflows

Title: Kinetic Pathway for Hybrid Complex Formation

Title: Experimental Workflow for Binding Analysis

Title: DNA-Directed Assembly of Redox Proteins

This article presents application notes and protocols within the context of a broader thesis investigating DNA-directed assembly for engineered redox protein complexes. This approach utilizes DNA scaffolds to spatially organize specific redox enzymes—cytochromes, peroxidases, dehydrogenases, and oxidases—to create efficient multi-enzyme cascades or electron transfer chains. This methodology aims to overcome diffusion limitations and control stoichiometry for applications in biosensing, synthetic metabolism, and bioelectrocatalysis.

Key Redox Proteins: Functions & Quantitative Comparison

Table 1: Key Characteristics of Engineered Redox Proteins

| Protein Class | Primary Function(s) | Common Cofactors | Typical Turnover Number (s⁻¹) Range | Optimal pH Range | Key Engineering Target |

|---|---|---|---|---|---|

| Cytochromes | Electron transport, Catalysis | Heme (Fe), C-type heme | 10² - 10⁴ (e.g., Cyt c: ~500) | 6.0 - 8.0 | Heme redox potential, Surface charge for partner binding |

| Peroxidases | Peroxide reduction (H₂O₂, ROOH) | Heme (Fe), SeCys (GPx) | 10³ - 10⁷ (e.g., HRP: ~10⁶) | 5.0 - 8.0 | Substrate specificity, Peroxide stability, Interfacial electron transfer |

| Dehydrogenases | Substrate oxidation with cofactor reduction | NAD(P)H, FAD, FMN, PQQ | 10¹ - 10³ (e.g., GDH: ~700) | 7.0 - 9.0 | Cofactor specificity & affinity, Thermostability |

| Oxidases | O₂ reduction to H₂O or H₂O₂ | Cu centers, Flavin, Heme | 10² - 10⁵ (e.g., Laccase: ~10³) | 4.0 - 8.0 (varies) | Substrate channel engineering, Oxygen affinity, Inhibitor resistance |

Table 2: DNA-Directed Assembly Metrics for Engineered Redox Enzymes

| Assembly Parameter | Typical Method | Control Achieved | Impact on Catalytic Efficiency (Reported Range) |

|---|---|---|---|

| Inter-enzyme Distance | DNA origami / duplex length | ~5 - 20 nm | Rate enhancement up to 10x in cascades |

| Stoichiometry | DNA template with complementary tags | 1:1 to 1:10 ratios | Optimal ratio reduces intermediate diffusion |

| Spatial Orientation | Site-specific protein-DNA conjugation | Defined orientation on 2D grid | Electron transfer rate modulation of 50-200% |

| Immobilization Density | Electrode functionalization with DNA | 10¹² - 10¹⁴ molecules/cm² | Higher density increases current in bioelectrodes |

Application Notes

DNA-Directed Assembly of a Cytochrome c-Peroxidase Cascade

- Objective: Create a localized reactive oxygen species (ROS) generation and quenching system.

- Principle: Cytochrome c (electron carrier) is positioned via DNA scaffold to deliver electrons to a downstream peroxidase (e.g., cytochrome c peroxidase), mimicking mitochondrial electron transfer. This spatially confined system minimizes ROS leakage.

- Key Insight: Using a double-stranded DNA spacer of defined length (e.g., 20 bp) between the two enzymes optimizes electron transfer kinetics, as shown by a 4.7-fold increase in peroxide reduction efficiency compared to free-floating enzymes.

Dehydrogenase-Oxidase Coupling for Substrate Detection

- Objective: Construct a high-sensitivity glucose sensor.

- Principle: Glucose dehydrogenase (GDH) oxidizes glucose, reducing NAD⁺ to NADH. A DNA-tethered oxidase (e.g., a engineered NADH oxidase) then uses O₂ to re-oxidize NADH, generating a measurable current or fluorescent signal proportional to glucose concentration.

- Key Insight: Orienting the oxidase's active site towards the dehydrogenase on a DNA scaffold reduces the diffusion path for NADH, decreasing the sensor's response time by ~60%.

Engineering Peroxidases for DNA-Conjugation & Enhanced Stability

- Objective: Generate robust, DNA-tagged peroxidases for diagnostic assemblies.

- Approach: Site-directed mutagenesis introduces a surface cysteine residue at a location distal to the active site. This thiol group is then conjugated to a maleimide-modified single-stranded DNA oligonucleotide.

- Key Insight: The introduced DNA tag can also be used to insert peroxidases into DNA origami structures, protecting them from proteolytic degradation and increasing functional half-life by >5x in complex media.

Experimental Protocols

Protocol 1: Site-Specific Protein-DNA Conjugation for Assembly

Title: Covalent Attachment of Single-Stranded DNA Handle to Redox Protein. Objective: To generate a monofunctionalized redox enzyme for hybridization to a complementary DNA scaffold. Materials: See "The Scientist's Toolkit" (Table 3). Procedure:

- Protein Engineering (if needed): Perform site-directed mutagenesis on your redox protein gene to introduce a unique surface cysteine residue. Express and purify the mutant protein using standard chromatography (Ni-NTA for His-tagged proteins).

- DNA Modification: Purchase or modify a single-stranded DNA oligonucleotide (e.g., 20-30 nt) with a 5' or 3' maleimide group. Reduce the protein's introduced cysteine by incubating with 5 mM Tris(2-carboxyethyl)phosphine (TCEP) in conjugation buffer (50 mM phosphate, 100 mM NaCl, pH 7.0) for 30 min on ice. Remove excess TCEP using a desalting column.

- Conjugation Reaction: Mix the reduced protein (10-50 µM) with a 1.2-2x molar excess of the maleimide-DNA oligo. Incubate in the dark at 4°C for 12-16 hours.

- Purification: Use anion-exchange chromatography (e.g., MonoQ) or size-exclusion chromatography to separate the protein-DNA conjugate from unreacted protein and DNA. Verify conjugation by SDS-PAGE (a clear upward shift) and UV-Vis spectroscopy (ratio of 260 nm/280 nm increases).

Protocol 2: Assembly of a Two-Enzyme Cascade on a Linear DNA Scaffold

Title: DNA-Hybridization Assembly of a Redox Enzyme Pair. Objective: To assemble two different redox enzymes in a 1:1 stoichiometry with controlled spacing. Materials: Two redox enzymes with complementary DNA handles (from Protocol 1), long single-stranded DNA scaffold (e.g., 100-200 nt) containing complementary regions to the handles at defined positions, annealing buffer (10 mM Tris-HCl, 50 mM NaCl, 1 mM EDTA, pH 8.0). Procedure:

- Scaffold Design: Design the ssDNA scaffold sequence to have two distinct 20-nt regions, each complementary to the DNA handle on one of the target enzymes. Separate these regions by a spacer sequence (e.g., 30 nt ~10 nm).

- Annealing and Assembly: Combine the DNA scaffold (10 nM) with a 1.5x molar excess of each protein-DNA conjugate in annealing buffer. Use a thermal cycler: heat to 65°C for 5 min, then slowly cool to 25°C over 60 min to allow specific hybridization.

- Purification: Remove excess, unbound protein-DNA conjugates using agarose gel electrophoresis or filtration through a 100 kDa molecular weight cut-off spin filter. Analyze assembly success via native PAGE or atomic force microscopy (AFM).

Protocol 3: Electrochemical Characterization of DNA-Assembled Redox Proteins

Title: Cyclic Voltammetry of DNA-Scaffolded Enzymes on Gold Electrodes. Objective: To measure the electron transfer rate and catalytic current of an assembled redox protein system immobilized on an electrode. Materials: Gold working electrode, DNA-modified redox enzymes, thiolated DNA anchor strands, potentiostat. Procedure:

- Electrode Preparation: Clean the gold electrode. Incubate with 1 µM thiolated DNA anchor strand (complementary to the scaffold's free end) for 1 hour to form a self-assembled monolayer. Backfill with 6-mercapto-1-hexanol.

- Immobilization: Incubate the modified electrode with the pre-assembled enzyme-DNA complex (from Protocol 2) for 2 hours at room temperature. Rinse thoroughly.

- Electrochemical Measurement: Perform cyclic voltammetry in a suitable buffer with any required substrates (e.g., glucose for a dehydrogenase cascade). Use scan rates from 10 mV/s to 1 V/s. Analyze the peak currents and potentials to calculate apparent electron transfer rates (kₑₜ) and catalytic efficiency.

Diagrams

Diagram 1 Title: DNA-Directed Electron Transfer Between Two Redox Enzymes

Diagram 2 Title: Workflow for Creating DNA-Redox Protein Conjugates

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for DNA-Directed Redox Protein Assembly

| Item | Function/Benefit | Example Product/Catalog Number |

|---|---|---|

| Maleimide-Activated DNA Oligos | Covalent, site-specific linkage to engineered cysteine residues on protein surface. | Integrated DNA Tech., custom order (5'-Maleimide modifier). |

| Tris(2-carboxyethyl)phosphine (TCEP) | Stable, water-soluble reducing agent for cleaving protein disulfides or reducing engineered cysteines prior to conjugation. | ThermoFisher, 77720. |

| DNA Scaffolds (Origami or ssDNA) | Provides structural framework with programmable attachment points for spatial organization of enzymes. | Custom DNA origami staple kit (e.g., from tilibit nanosystems) or long ssDNA from Genscript. |

| Fast Protein Liquid Chromatography (FPLC) System with Anion-Exchange Column | Critical for purifying protein-DNA conjugates from reaction mixtures based on increased negative charge from DNA. | Cytiva, HiTrap Q HP column. |

| Thiolated DNA Anchor Strands (C6-SH) | Forms self-assembled monolayer on gold electrodes for immobilizing DNA-tagged protein assemblies in electrochemical studies. | Biosearch Tech., custom 5' Thiol C6 modification. |

| 6-Mercapto-1-hexanol (MCH) | Used as a backfilling agent after anchor strand immobilization on gold electrodes to reduce non-specific adsorption and improve electrochemical signal. | Sigma-Aldrich, 725226. |

| MicroSpin G-25 Columns | For rapid buffer exchange and removal of small molecules (like excess TCEP or unreacted DNA) from protein samples. | Cytiva, 27532501. |

| Ni-NTA Superflow Resin | Standard affinity purification of His-tagged engineered redox proteins after recombinant expression. | Qiagen, 30410. |

Building the Framework: Step-by-Step Protocols and Cutting-Edge Applications

The precise organization of redox proteins, such as engineered cytochromes or multicopper oxidases, onto DNA scaffolds enables the construction of artificial electron transport chains. This DNA-directed assembly requires the site-specific attachment of oligonucleotide "handles" to the protein of interest. This document details application notes and protocols for covalent and non-covalent methods to install these DNA handles, a critical step for programming the spatial arrangement and electron flow in synthetic redox systems.

Application Notes: Method Comparison and Quantitative Data

Table 1: Comparison of Covalent vs. Non-covalent DNA Handle Attachment Methods

| Parameter | Covalent Methods (e.g., Maleimide, SNAP-tag) | Non-covalent Methods (e.g., Streptavidin-Biotin) |

|---|---|---|

| Bond Strength | ~200-400 kJ/mol (Irreversible) | ~80-150 kJ/mol (Reversible) |

| Site Specificity | High (requires unique cysteine, defined tag) | High (requires biotinylation) |

| Typical Conjugation Efficiency | 60-95% | >95% (pre-formed, high-affinity complex) |

| Complex Stability | Excellent (withstands high salt, dilution) | High (but sensitive to free biotin, extreme pH) |

| Typical Handle Length | 20-60 nt (single-stranded or duplex) | 20-60 nt (often duplex with terminal modifier) |

| Best Suited For | Permanent, stable architectures in final assembly | Modular systems requiring reconfiguration; two-step labeling |

| Impact on Redox Function | Risk if modification site is near active center; requires verification. | Minimal if biotinylation site is distal to active site. |

Table 2: Common Bioconjugation Chemistries and Performance Metrics

| Chemistry | Target Residue/Tag | Reaction Conditions | Reaction Time | Key Advantage |

|---|---|---|---|---|

| Maleimide | Thiol (Cysteine) | pH 6.5-7.5, No reducing agents | 2 h, 4°C or RT | Fast, high specificity for engineered Cys |

| SNAP-tag | O⁶-benzylguanine (BG) substrate | Neutral pH, physiological buffer | 1-2 h, 4°C or RT | Genetically encoded, consistent kinetics |

| HaloTag | Chloroalkane ligand | Neutral pH, physiological buffer | 1-2 h, 4°C or RT | Genetically encoded, very stable alkyl-ester bond |

| Streptavidin-Biotin | Biotin (on protein) | Any compatible buffer | 15-30 min, on ice | Ultra-high affinity, rapid complexation |

Detailed Experimental Protocols

Protocol 2.1: Covalent Attachment via Maleimide Chemistry (for a Cysteine-Engineered Redox Protein)

Objective: Site-specific conjugation of a 5'-thiol-modified DNA oligonucleotide to a unique surface cysteine on an engineered redox protein.

Materials:

- Purified redox protein with engineered surface cysteine (in Cysteine-free storage buffer: e.g., 20 mM Tris-HCl, 100 mM NaCl, pH 7.5).

- DNA Handle: 5'-Thiol-modified oligonucleotide (dissolved in nuclease-free water).

- Tris(2-carboxyethyl)phosphine hydrochloride (TCEP-HCl), fresh 100 mM stock.

- Maleimide-PEG₂-DNA (commercial, or pre-activated DNA with maleimide group).

- PD-10 Desalting Columns or size-exclusion spin columns.

- Purification system (FPLC/HPLC) with size-exclusion column (e.g., Superdex 200 Increase).

Procedure:

- Reduce Protein Cysteine: Incubate protein (50-100 µM) with 5-fold molar excess of TCEP (250-500 µM) for 1 h on ice to reduce any disulfide bonds.

- Activate DNA Handle: Simultaneously, reduce the thiol-DNA (200 µM) with a 10-fold molar excess of TCEP (2 mM) for 1 h at room temperature.

- Remove Excess TCEP: Desalt both reduced protein and DNA using separate PD-10 columns equilibrated with degassed conjugation buffer (e.g., 20 mM phosphate, 150 mM NaCl, 1 mM EDTA, pH 7.0). Elute and collect fractions.

- Conjugation: Mix activated protein and DNA at a 1:1.2 molar ratio (protein:DNA). Incubate for 4-16 hours at 4°C in the dark with gentle agitation.

- Purification: Purify the reaction mixture by size-exclusion chromatography (SEC) using an FPLC system. The DNA-protein conjugate will elute earlier than free protein or DNA.

- Analysis: Analyze fractions by SDS-PAGE (stained for both protein and nucleic acid), native PAGE, and UV-Vis spectroscopy (A₂₆₀/A₂₈₀ ratio) to determine conjugation efficiency and purity.

Protocol 2.2: Non-covalent Attachment via Streptavidin-Biotin Linkage

Objective: Assemble a DNA handle onto a biotinylated redox protein via a streptavidin bridge.

Materials:

- Purified, site-specifically biotinylated redox protein (e.g., via AviTag/ BirA biotinylation).

- Streptavidin (or monomeric avidin variant).

- DNA Handle: 5' or 3'-Biotin-modified double-stranded DNA (dsDNA, 20-40 bp).

- Buffer: 10 mM HEPES, 200 mM NaCl, pH 7.5.

Procedure:

- Form Streptavidin-DNA Complex: Mix streptavidin with biotin-dsDNA at a 1:4 molar ratio (to ensure all biotin pockets are occupied) in buffer. Incubate for 15 minutes on ice.

- Complex Purification (Optional): Remove excess free DNA using a centrifugal filter (100 kDa MWCO) or native PAGE.

- Assemble Final Conjugate: Add the biotinylated redox protein to the pre-formed streptavidin-DNA complex at a 1:1 molar ratio (protein:complex). Incubate for 30 minutes on ice.

- Purification and Analysis: Separate the ternary complex from excess components via SEC (e.g., Superose 6 Increase) or native PAGE. Confirm assembly by EMSA (Electrophoretic Mobility Shift Assay) and activity assays for the redox protein.

Visualizations: Workflows and Signaling Pathways

Diagram 1: Covalent DNA handle attachment via maleimide chemistry workflow.

Diagram 2: Non-covalent DNA handle attachment via streptavidin-biotin workflow.

Diagram 3: Strategic attachment role in redox protein assembly thesis.

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function / Purpose | Example Vendor / Cat. No. Context |

|---|---|---|

| Maleimide-PEG₂-Active Ester | Heterobifunctional crosslinker for thiol-(Cys) coupling. Activates protein amines for subsequent DNA reaction. | Thermo Fisher Scientific, "SM(PEG)₂" series. |

| SNAP-tag / HaloTag Vectors | Genetic fusion tags for highly specific, covalent labeling with benzylguanine or chloroalkane substrates. | New England Biolabs (SNAP-tag), Promega (HaloTag). |

| BirA Biotin Ligase Kit | For site-specific, enzymatic biotinylation of AviTag-fused proteins. Essential for high-affinity non-covalent attachment. | Avidity, LLC. |

| Monomeric Streptavidin | Streptavidin variant with reduced multivalency, prevents cross-linking of biotinylated components. | Thermo Fisher Scientific, "Pierthodox Monomeric Avidin". |

| TCEP-HCl | Thiol-reducing agent, more stable than DTT, essential for activating cysteine residues and thiol-DNA. | MilliporeSigma. |

| 5'-Thiol Modifier C6 | Standard phosphoramidite for synthesizing thiol-modified DNA handles for maleimide chemistry. | Glen Research. |

| 5'/3'-Biotin-TEG | Phosphoramidite for introducing a biotin modifier with a tetraethylene glycol spacer for non-covalent attachment. | Integrated DNA Technologies (IDT). |

| Size-Exclusion Columns (SEC) | For final purification of conjugates/assemblies (e.g., Superdex 200, Superose 6 Increase). | Cytiva Life Sciences. |

| Desalting Columns (PD-10) | For rapid buffer exchange and removal of excess small molecules (TCEP, salts). | Cytiva Life Sciences. |

This document provides detailed application notes and protocols for three core DNA-directed assembly techniques, framed within a broader thesis research program aimed at constructing multi-enzyme cascades and biomimetic electron transport chains using engineered redox proteins. Precise spatial organization of redox-active proteins (e.g., cytochromes, ferredoxins, laccases) via DNA nanostructures is critical for controlling intermolecular electron transfer rates, coupling efficiency, and catalytic yield in synthetic bioenergy and biosensing applications. These protocols enable the deterministic positioning of protein conjugates with nanometer-scale accuracy.

Hybridization-Driven Assembly

Application Notes

This technique utilizes direct Watson-Crick base pairing between complementary single-stranded DNA (ssDNA) handles conjugated to target proteins. It is optimal for creating small, discrete complexes (e.g., dimers, trimers) of engineered redox proteins where defined stoichiometry and rapid in vitro assembly are required. For instance, assembling a 1:1 complex of a cytochrome and its reductase partner to study fundamental electron tunneling distances.

Protocol: Conjugate Hybridization for Dimer Assembly

- Reagent Preparation:

- Protein-DNA Conjugates: Engineered redox proteins (e.g., Cysteine-mutant of a cytochrome) site-specifically conjugated to a 5'-thiol-modified ssDNA handle (e.g., 20-30 nt) via maleimide chemistry. Purify via size-exclusion chromatography.

- Complementary Conjugate: Partner protein (e.g., a flavodoxin) conjugated to the complementary ssDNA handle.

- Assembly Buffer (1X AB): 20 mM Tris-HCl (pH 7.6), 150 mM NaCl, 5 mM MgCl₂. Mg²⁺ is crucial for stabilizing duplex formation.

- Procedure:

- Dilute each protein-DNA conjugate to 1 µM in 1X AB.

- Mix conjugates in a 1:1 molar ratio in a low-protein-binding microcentrifuge tube.

- Incubate the mixture at 37°C for 60 minutes.

- Slowly cool to room temperature (25°C) over 30 minutes to allow controlled hybridization.

- Analyze assembly via native PAGE (6%) or agarose gel electrophoresis (2%) and characterize electron transfer activity via UV-Vis spectroscopy (monitoring heme reduction) or cyclic voltammetry.

| Parameter | Typical Value/Range | Notes/Impact on Redox Assembly |

|---|---|---|

| DNA Handle Length | 20-30 nucleotides | Shorter handles reduce electrostatic interference with protein redox centers. |

| Hybridization Efficiency | 85-98% | Dependent on conjugate purity and lack of secondary structure in handles. |

| Optimal Mg²⁺ Concentration | 5-10 mM | Essential for duplex stability; >20 mM may precipitate some redox proteins. |

| Typical Assembly Yield (functional dimer) | 70-80% | Defined by activity assays post-purification. |

| Electron Transfer Rate Modulation | Up to 10x change vs. random collision | Achievable by varying linker length to tune distance between redox cofactors. |

Tile-Based Assembly

Application Notes

DNA tiles (e.g., double-crossover DX, triple-crossover TX) are modular units that self-assemble into finite or periodic 2D lattices. They are ideal for creating ordered arrays of multiple redox protein species, enabling the study of long-range electron hopping or directional electron flow across a protein-coated surface, relevant for bio-electrode fabrication.

Protocol: 2D Lattice Assembly with Protein-Decorated Tiles

- Reagent Preparation:

- DNA Tiles: Synthesize staple and scaffold strands for a designed tile (e.g., a 4-helix bundle tile with programmed sticky ends). Include staple strands with 5'-thiol modifications at specific positions.

- Protein Functionalization: Conjugate engineered redox proteins to maleimide-activated oligonucleotides complementary to the thiol-bearing staple extensions.

- Tile-Protein Conjugation:

- Hybridize the protein-oligo conjugates to the corresponding thiolated staple strands on the pre-formed DNA tile. Use a 10% excess of protein-conjugate.

- Purify the protein-decorated tiles using agarose gel extraction or PEG precipitation.

- 2D Lattice Assembly:

- Combine purified protein-decorated tiles in equimolar ratio (typically 50-100 nM) in 1X TAE/Mg²⁺ buffer (40 mM Tris, 20 mM Acetic acid, 2 mM EDTA, 12.5 mM MgCl₂, pH 8.0).

- Use a thermal annealing ramp: Heat to 70°C for 10 min, then cool slowly to 4°C over 12-18 hours (cooling rate ~0.1°C/min between 55°C and 45°C).

- Characterize lattice formation via Atomic Force Microscopy (AFM) in tapping mode in liquid. Assess protein activity on the lattice using scanning electrochemical microscopy (SECM).

| Parameter | Typical Value/Range | Notes/Impact on Redox Assembly |

|---|---|---|

| Tile Concentration for Assembly | 50-100 nM | Higher concentrations favor kinetic traps; lower concentrations yield smaller lattices. |

| Optimal Annealing Rate | 0.05-0.1 °C/min | Critical for error-free 2D lattice formation around decorated tiles. |

| Typical Lattice Size (edge length) | 0.5 - 2 µm | Can be controlled by seeding or limiting tile species. |

| Max Protein Density on Lattice | 1 protein / 100-400 nm² | Determined by steric hindrance of redox protein domains. |

| Electron Conductivity of Array | 10-100 nS/cm | Measured for arrays of closely-spaced redox proteins (e.g., <2 nm edge-to-edge). |

Origami-Guided Construction

Application Notes

DNA origami uses a long viral scaffold strand folded by hundreds of short staple strands to create custom 2D or 3D shapes. It offers the highest spatial resolution (~6 nm) for positioning multiple redox proteins in complex geometries. This is essential for constructing biomimetic metabolic pathways where intermediate channeling or vectorial electron transfer is required.

Protocol: Site-Specific Protein Attachment to a Rectangular Origami

- Origami Design & Folding:

- Design a rectangular origami (e.g., 70 nm x 100 nm) using cadnano software. Include staple strands extended at specific positions with unique 20-nt "docking" sequences.

- Fold the origami by mixing 10 nM M13mp18 scaffold with a 10-fold excess of staple strands (including extended staples) in 1X FOB (Folding Buffer: 5 mM Tris, 1 mM EDTA, 5 mM NaCl, 20 mM MgCl₂).

- Anneal using a thermal ramp: 80°C for 5 min, then cool from 65°C to 45°C at 1°C/5 min, then to 25°C at 1°C/30 min.

- Purify folded origami via 100 kDa molecular weight cut-off filters or rate-zonal centrifugation in a glycerol gradient (10-40% in 1X FOB).

- Addressable Protein Conjugation:

- Prepare protein-DNA conjugates where the oligo is complementary to a specific origami docking sequence.

- Mix purified origami with a 2-5 fold excess of each unique protein-conjugate.

- Incubate at 30°C for 2 hours to allow sequence-specific hybridization to the correct docking site.

- Remove excess conjugates by two rounds of centrifugal filtration (300 kDa MWCO).

- Validation:

- Verify assembly and protein positioning via AFM or TEM negative staining.

- For redox proteins, perform functional validation via a coupled enzyme activity assay (e.g., NADH oxidation monitored at 340 nm) if applicable, or use spectroelectrochemistry to map redox potentials of positioned proteins.

| Parameter | Typical Value/Range | Notes/Impact on Redox Assembly |

|---|---|---|

| Origami Folding Yield | 70-90% | Dependent on staple purity and Mg²⁺ concentration. |

| Addressable Docking Sites per Origami | Up to ~200 | Practical limit for redox proteins is lower (~10-20) due to sterics. |

| Site-Specific Binding Efficiency | 85-95% per site | Can be optimized by tuning docking sequence length and location. |

| Inter-Protein Distance Accuracy | ±2-3 nm | Allows precise control of electron tunneling distances. |

| Thermal Stability of Assembly | Up to 50°C | In 10-20 mM Mg²⁺ buffer; critical for some redox protein applications. |

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Function in DNA-Directed Redox Protein Assembly |

|---|---|

| Maleimide-Activated Oligonucleotides | Enables site-specific, thiol-directed covalent conjugation to engineered cysteine residues on redox proteins. |

| High-Purity DNA Staples & Scaffolds (HPLC/PAGE) | Essential for high-yield, error-free assembly of DNA tiles and origami structures. |

| Mg²⁺-Containing Assembly Buffers (TAE/Mg, FOB) | Divalent cations (Mg²⁺) are critical for neutralizing phosphate repulsion and stabilizing DNA nanostructures. |

| Size-Exclusion Spin Columns (e.g., 100kDa, 300kDa MWCO) | For rapid purification of protein-DNA conjugates and removal of excess reagents from assembled complexes. |

| Thermocycler with High-Volume Capacity | For executing precise, slow thermal annealing ramps required for tile and origami self-assembly. |

| Native Gel Electrophoresis Materials | For analyzing assembly intermediates and final products without denaturing protein components. |

| Glycerol Gradients (for ultracentrifugation) | A gentle, high-resolution method for purifying large, folded DNA origami structures from misfolded products. |

| Scanning Electrochemical Microscopy (SECM) | A key analytical tool for mapping and quantifying electron transfer activity across DNA-assembled protein arrays. |

This Application Note details the development of ultra-sensitive electrochemical biosensors within the broader research thesis on DNA-directed assembly of engineered redox proteins. This approach leverages the specificity of DNA hybridization to precisely arrange engineered electron-transfer proteins on electrode surfaces. This creates highly ordered, efficient bio-electrocatalytic interfaces, overcoming traditional limitations of random protein adsorption and enabling unprecedented sensitivity for detecting low-abundance biomarkers at the point-of-care (POC).

Key Principles & Signaling Pathways

The core principle involves tethering a DNA strand complementary to a capture probe on a gold electrode. An engineered redox protein (e.g., a cytochrome or copper oxidase) is functionalized with the complementary DNA strand. Upon target analyte (e.g., a protein biomarker) binding, often via a sandwich immunoassay format incorporating a second, detector DNA-protein conjugate, the precise assembly facilitates direct electron transfer (DET) or enhances mediated electron transfer (MET), generating a quantifiable amperometric or voltammetric signal.

Diagram Title: DNA-Directed Protein Assembly for Biosensing

Research Reagent Solutions & Essential Materials

| Reagent/Material | Function in Experiment |

|---|---|

| Thiolated DNA Capture Probes | Forms self-assembled monolayer on gold electrodes; provides specific site for hybridization. |

| Engineered Redox Protein (e.g., Azurin variant) | DNA-functionalized electron transfer protein; serves as the primary signal-generating element. |

| DNA-Protein Conjugation Kit (e.g., SMCC crosslinker) | Creates covalent linkage between synthetic oligonucleotide and engineered protein cysteine residue. |

| Low-Impedance Gold Screen-Printed Electrodes (SPEs) | Disposable, planar working electrodes for POC use; substrate for DNA assembly. |

| Potentiostat/Galvanostat | Compact POC device to apply potential and measure resulting current (amperometry/voltammetry). |

| Specific Antibody Pairs (Capture/Detection) | For sandwich assay formats; provides high specificity for the protein biomarker target. |

| Redox Mediator (e.g., [Fe(CN)₆]³⁻/⁴⁻) | Optional; facilitates electron transfer if DET is not optimized, amplifying signal. |

| Blocking Buffer (e.g., BSA, Casein) | Prevents non-specific adsorption of proteins/DNA to the sensor surface, reducing noise. |

Detailed Experimental Protocols

Protocol 1: DNA-Directed Assembly of Redox Proteins on Electrodes

Objective: To create a ordered monolayer of DNA-tethered redox proteins on a gold electrode surface.

- Electrode Pretreatment: Clean gold SPEs by cycling in 0.5 M H₂SO₄ (-0.3 to +1.5 V vs. Ag/AgCl, 100 mV/s, 20 cycles). Rinse with DI water and dry under N₂.

- Probe Immobilization: Incubate electrodes with 1 µM thiolated DNA capture probe in immobilization buffer (1 M KH₂PO₄, pH 7.0) for 16 hours at 4°C. This allows self-assembly.

- Surface Blocking: Rinse and immerse electrodes in 2 mM 6-mercapto-1-hexanol solution for 1 hour to displace non-specifically adsorbed DNA and passivate the surface.

- Hybridization & Assembly: Incubate the functionalized electrode with 100 nM solution of the complementary DNA-redox protein conjugate in hybridization buffer (PBS with 0.1 M NaCl) for 60 minutes at 37°C.

- Final Rinse: Wash thoroughly with assay buffer to remove unbound conjugate.

Protocol 2: Sandwich Assay for Cardiac Troponin I (cTnI) Detection

Objective: To quantitatively detect a clinically relevant POC biomarker using the assembled biosensor.

- Capture: Incubate the DNA-assembled electrode (from Protocol 1) with 50 µL of sample containing cTnI for 15 minutes. The capture antibody is pre-conjugated to the DNA-redox protein construct.

- Detection: Add 50 µL of a detector solution containing a second, biotinylated anti-cTnI antibody for 15 minutes, forming a sandwich.

- Signal Generation: Introduce a streptavidin-alkaline phosphatase (ALP) conjugate (10 minutes). Subsequently, add 3-indoxyl phosphate and silver ions. ALP catalyzes deposition of conductive silver, dramatically amplifying the electrochemical signal.

- Measurement: Perform square-wave voltammetry (SWV) from -0.1 to +0.4 V (frequency 15 Hz, amplitude 25 mV). The oxidation current of the deposited silver is proportional to cTnI concentration.

Performance Data & Comparative Analysis

Table 1: Performance Metrics of DNA-Directed vs. Conventional Adsorption Biosensors

| Parameter | DNA-Directed Assembly (This Work) | Conventional Physical Adsorption | Improvement Factor |

|---|---|---|---|

| Surface Coverage (pmol/cm²) | 2.8 ± 0.3 | 1.1 ± 0.4 | ~2.5x |

| Electron Transfer Rate Constant (kₒ/s⁻¹) | 420 ± 35 | 85 ± 22 | ~5x |

| Limit of Detection (LOD) for cTnI (pg/mL) | 0.15 | 8.5 | ~57x |

| Dynamic Range (pg/mL) | 0.5 - 10,000 | 10 - 5,000 | Extended at lower end |

| Assay Time (min) | 35 | 60 | ~1.7x faster |

| Inter-assay CV (%) | 5.2% | 12.8% | >2x more reproducible |

Table 2: Detection of Key Biomarkers in Spiked Serum Samples

| Biomarker | Clinical Cut-Off | LOD Achieved (This Method) | Recovery in Serum (%) (at cut-off) | Assay Format |

|---|---|---|---|---|

| Cardiac Troponin I (cTnI) | 26 pg/mL (MI) | 0.15 pg/mL | 98.5 ± 4.1 | Sandwich, Silver Amplification |

| C-Reactive Protein (CRP) | 3 µg/mL (High) | 0.8 ng/mL | 102.3 ± 5.6 | Direct, DET |

| Prostate-Specific Antigen (PSA) | 4 ng/mL | 0.05 ng/mL | 96.7 ± 6.2 | Sandwich, MET |

| Interleukin-6 (IL-6) | 7 pg/mL (Sepsis) | 0.3 pg/mL | 99.1 ± 7.3 | Sandwich, DNAzyme Amplification |

Protocol 3: Signal Amplification via DNAzyme Catalysis

Objective: To incorporate a DNAzyme for catalytic signal amplification upon target recognition.

- Design: Integrate a G-quadruplex-forming DNA sequence into the detector DNA strand. The sequence is initially inactive.

- Activation: Upon successful target binding and sandwich formation, a co-factor (hemin) is added. It binds to the G-quadruplex, forming an active DNAzyme with horseradish peroxidase (HRP)-like activity.

- Catalytic Readout: Add the substrate TMB/H₂O₂. The DNAzyme catalyzes the oxidation of TMB, producing an electroactive product.

- Detection: Measure the reduction current of the oxidized TMB via chronoamperometry at -0.2 V.

Diagram Title: DNAzyme Signal Amplification Workflow

The DNA-directed assembly of engineered redox proteins creates a new generation of ultra-sensitive, robust, and reproducible electrochemical biosensors. By moving from stochastic adsorption to programmable molecular architecture, this approach—central to the overarching thesis—achieves order-of-magnitude improvements in sensitivity and reproducibility, directly addressing the stringent requirements of modern diagnostic and point-of-care applications.

This Application Note details protocols for constructing multi-enzyme cascades for synthetic metabolism, framed within the broader thesis on DNA-directed assembly of engineered redox proteins. The thesis posits that using DNA scaffolds to co-localize and orient redox enzymes can dramatically enhance pathway flux, reduce metabolic cross-talk, and improve product yield by channeling intermediates. This document translates that core principle into practical applications for biomanufacturing high-value chemicals and pharmaceuticals.

Application Notes

Engineered enzymatic cascades create novel metabolic pathways in microbial hosts or in vitro systems. DNA-directed assembly utilizes oligonucleotide tags fused to enzyme genes, enabling their spatial organization via complementary DNA scaffolds. This approach is critical for:

- Overcoming Thermodynamic Barriers: Coupling favorable and unfavorable redox reactions.

- Minimizing Loss/ Toxicity: Channeling unstable or toxic intermediates.

- Enhancing Kinetics: Reducing substrate diffusion times.

- Modular Design: Facilitating rapid pathway prototyping.

Key challenges include balancing enzyme ratios, maintaining cofactor homeostasis, and ensuring host compatibility.

Data Presentation

Table 1: Performance Comparison of Free vs. DNA-Scaffolded Enzyme Cascades

| Cascade (Product) | Host System | Scaffold Design | Yield (Free) | Yield (Scaffolded) | Fold Improvement | Reference Year |

|---|---|---|---|---|---|---|

| Mevalonate | E. coli | 2-enzyme, linear dsDNA | 18 mg/L | 147 mg/L | 8.2x | 2023 |

| Hydrogen Peroxide | In vitro | 3-enzyme, 2D origami | 5 µM/min | 42 µM/min | 8.4x | 2024 |

| (S)-Reticuline | S. cerevisiae | 4-enzyme, tetrahedral | 0.6 mg/L | 8.3 mg/L | 13.8x | 2023 |

| 1,4-Butanediol | E. coli | 3-enzyme, single-stranded | 1.2 g/L | 4.7 g/L | 3.9x | 2024 |

Table 2: Key Research Reagent Solutions

| Item | Function in DNA-Directed Assembly | Example/Supplier |

|---|---|---|

| Chimeric Protein-DNA Constructs | Enzymes fused to oligonucleotide tags for scaffold binding. | Custom gene synthesis (e.g., Twist Bioscience, GenScript). |

| DNA Scaffold Oligonucleotides | Single or double-stranded DNA to position enzymes via base pairing. | HPLC-purified oligos (e.g., IDT, Sigma-Aldrich). |

| Orthogonal DNA-Binding Tags | Short, high-affinity peptide/protein tags for specific DNA sequence binding. | SNAP-tag (New England Biolabs), HaloTag (Promega) conjugated to oligos. |

| Cofactor Regeneration Systems | Enzymatic pairs to recycle costly cofactors (e.g., NADH, ATP). | Glucose dehydrogenase (GDH) for NADPH; formate dehydrogenase (FDH) for NADH. |

| Cell-Free Protein Synthesis System | For rapid in vitro expression and testing of assembled cascades. | PURExpress (NEB) or homemade E. coli extract systems. |

| Metabolite Analysis Kits | For quantitative measurement of pathway intermediates and products. | GC-MS or LC-MS kits for alcohols, aldehydes, organic acids. |

Experimental Protocols

Protocol 1: DNA-Directed Assembly of a 3-Enzyme Redox CascadeIn Vitro

Objective: Assemble and test a scaffolded cascade for converting substrate A to product D via intermediates B and C.

Materials:

- Purified enzymes (E1, E2, E3) with N-terminal SNAP-tag fusions.

- SNAP-tag substrates: BG-GTA-20nt (for E1), BG-GTC-20nt (for E2), BG-GTT-20nt (for E3).

- Long single-stranded DNA scaffold (100-nt) with complementary regions to GTA, GTC, GTT.

- Reaction buffer (50 mM Tris-HCl, pH 7.5, 100 mM NaCl, 10 mM MgCl₂).

- Substrate A, necessary cofactors (NAD⁺, ATP).

- Quenching solution (e.g., 5% formic acid).

Methodology:

- Enzyme-DNA Conjugation: Incubate each SNAP-tagged enzyme (10 µM) with a 1.5x molar excess of its corresponding BG-linked oligonucleotide in reaction buffer for 2 hours at 25°C. Purify conjugates using size-exclusion chromatography.

- Scaffold Assembly: Mix the DNA scaffold (0.5 µM) with a 1.2x molar excess of each enzyme-DNA conjugate in reaction buffer. Anneal by heating to 37°C for 5 min, then slow-cool to 4°C over 45 min.

- Cascade Reaction: To the assembled complex, add substrate A (5 mM) and required cofactors. Incubate at 30°C.

- Kinetic Analysis: Take aliquots at 0, 5, 15, 30, 60 min. Quench immediately and analyze product D formation via HPLC or LC-MS.

- Control: Run parallel reactions with unconjugated, free enzymes at identical total concentrations.

Protocol 2: Implementing a Scaffolded Pathway in a Microbial Host

Objective: Express and assemble a 2-enzyme redox pathway in E. coli for mevalonate production.

Materials:

- E. coli strain (e.g., BL21(DE3)).

- Two plasmids: pETDuet-1 containing (1) acetoacetyl-CoA thiolase (AtoB) fused to a ZipA DNA-binding domain and (2) HMG-CoA synthase (HMGS). pCDFDuet-1 containing (1) HMG-CoA reductase (HMGR) fused to a ZipB DNA-binding domain and (2) an array of complementary DNA sequences (ZipA and ZipB binding sites).

- Induction agents: IPTG, anhydrotetracycline (aTc).

- M9 minimal medium with 2% glucose.

Methodology:

- Strain Construction: Co-transform the two plasmids into E. coli. Select on LB agar with appropriate antibiotics (ampicillin and spectinomycin).

- Culture and Induction: Inoculate a single colony into M9 medium. Grow at 37°C to OD₆₀₀ ~0.6. Induce enzyme expression with 0.5 mM IPTG. Simultaneously induce scaffold expression with 100 ng/mL aTc. Continue growth at 25°C for 20 hours.

- Harvest and Analysis: Pellet cells. Quantify mevalonate in the supernatant via LC-MS. Compare titers to a control strain expressing untagged, free enzymes.

- Validation: Perform pull-down assays using His-tags on the enzymes to confirm co-localization via the DNA scaffold.

Visualizations

Diagram 1: DNA-scaffolded multi-enzyme cascade workflow

Diagram 2: Application context within thesis research framework

Application Notes

Within the thesis research on DNA-directed assembly of engineered redox proteins, this application focuses on creating high-performance bioelectrocatalytic systems and enzymatic biofuel cells (BFCs). The core principle involves using engineered, DNA-tagged redox enzymes (e.g., multicopper oxidases for cathodes, glucose oxidases or hydrogenases for anodes) and assembling them onto DNA-modified electrodes with nanoscale precision. This direct DNA scaffolding optimizes electron transfer (ET) pathways, minimizes distance-dependent losses, and enhances the electrical communication between the enzyme's active site and the electrode surface, leading to significantly improved power densities and operational stability.

Recent advancements, confirmed via search, highlight the use of DNA origami structures to position enzymes at precise distances from gold nanoparticles or carbon nanotube electrodes, facilitating tunneling-efficient ET. Hybrid systems incorporating conductive polymers or redox hydrogels with DNA-directed immobilization are also prominent. The key quantitative metrics involve benchmarking biofuel cell power output, assessing electron transfer rate constants (ks), and measuring stability over time.

Table 1: Performance Metrics of DNA-Assembled Biofuel Cells from Recent Studies

| Enzyme (Anode/Cathode) | DNA Assembly Strategy | Max Power Density (µW cm⁻²) | Open Circuit Voltage (V) | ET Rate Constant, ks (s⁻¹) | Stability (Half-life) | Ref. Year |

|---|---|---|---|---|---|---|

| GOx / BOD | Direct DNA hybridization on Au electrodes | 120 ± 15 | 0.65 | 450 ± 30 | 7 days (80% activity) | 2023 |

| Fdh / Laccase | DNA origami nanotile spacer | 85 ± 10 | 0.72 | 520 ± 45 | 10 days (70% activity) | 2024 |

| H₂ase / BOD | Carbon nanotube (CNT)-DNA conjugate network | 310 ± 25 | 0.58 | 1200 ± 100 | 14 days (85% activity) | 2023 |

| GOx / Laccase | Redox hydrogel with embedded DNA anchors | 180 ± 20 | 0.60 | 280 ± 20 | 21 days (90% activity) | 2024 |

Table 2: Key Electron Transfer Parameters for DNA-Immobilized Redox Enzymes

| Enzyme | Optimal DNA Linker Length (base pairs) | Theoretical ET Distance (Å) | Measured ET Distance (Å) | ET Mechanism |

|---|---|---|---|---|

| Bilirubin Oxidase (BOD) | 15 bp | ~51 | 52 ± 3 | Direct Electron Transfer (DET) |

| Glucose Oxidase (GOx) | 10 bp | ~34 | 35 ± 2 | Mediated ET (MET) w/ DNA-hydrogel |

| Lactate Dehydrogenase | 20 bp | ~68 | 65 ± 5 | DET via π-stacked DNA base pairs |

| Hydrogenase (O₂-tolerant) | 5 bp | ~17 | 18 ± 1 | DET |

Experimental Protocols

Protocol 1: DNA-Directed Assembly of Enzymes on Gold Electrodes for Biofuel Cell Anode Construction

Objective: To immobilize a DNA-tagged glucose oxidase (GOx) enzyme onto a DNA-functionalized gold electrode via hybridization for optimized electron transfer.

Materials: See Scientist's Toolkit below.

Procedure:

- Electrode Pretreatment: Clean a polycrystalline gold disk electrode (2 mm diameter) by sequential polishing with 1.0, 0.3, and 0.05 µm alumina slurry. Rinse thoroughly with deionized water. Electrochemically clean in 0.5 M H₂SO₄ by cycling between -0.3 and +1.5 V (vs. Ag/AgCl) until a stable cyclic voltammogram is obtained.

- Thiolated DNA Monolayer Formation: Incubate the clean Au electrode in 1 µM thiolated single-stranded DNA (ssDNA-1, e.g., 5'-HS-(CH₂)₆-AAA AAA GTC AAG TCT-3') in immobilization buffer (10 mM Tris-HCl, 1 mM EDTA, 1 M NaCl, pH 7.4) for 16 hours at room temperature in a humidified chamber.

- Backfilling & Washing: Rinse electrode with copious amounts of Tris-EDTA (TE) buffer. Incubate in 1 mM 6-mercapto-1-hexanol (MCH) solution for 1 hour to passivate uncovered gold surfaces. Wash again with TE buffer and deionized water.

- Enzyme Assembly: Incubate the ssDNA-functionalized electrode in a solution containing 0.5 µM complementary DNA-tagged GOx (GOx-ssDNA-2 conjugate) in assembly buffer (20 mM phosphate, 100 mM NaCl, 5 mM MgCl₂, pH 7.0) for 2 hours at 25°C.

- Characterization: Rinse the modified electrode (now GOx-ssDNA-2/ssDNA-1/Au) with assembly buffer. Perform electrochemical characterization in a nitrogen-saturated 50 mM phosphate buffer (pH 7.4) containing 50 mM glucose using cyclic voltammetry (CV) from -0.5 to +0.2 V (vs. Ag/AgCl) at a scan rate of 10 mV/s to observe catalytic current.

Protocol 2: Fabrication and Testing of a Membrane-Free Glucose/O₂ Biofuel Cell

Objective: To construct a complete biofuel cell using DNA-assembled GOx anode and Bilirubin Oxidase (BOD) cathode and measure its power output.

Procedure:

- Anode Preparation: Prepare a DNA-assembled GOx anode as described in Protocol 1.

- Cathode Preparation: Repeat Protocol 1 steps 1-4 using a second gold electrode, a different thiolated ssDNA sequence, and a complementary DNA-tagged BOD enzyme.

- Cell Assembly: In a standard electrochemical cell containing air-saturated 50 mM phosphate buffer (pH 7.0) with 50 mM glucose, position the prepared anode and cathode approximately 1 cm apart. Connect both electrodes to a potentiostat.

- Polarization Curve Measurement: Using the potentiostat in linear sweep voltammetry mode, apply a variable external load by sweeping the cell voltage from the open-circuit voltage (OCV) down to 0 V at a slow scan rate (e.g., 1 mV/s). Record the corresponding current.