AD5933 vs. Benchtop Impedance Analyzers: A Lab Scientist's Complete Guide to Biosensor & Cell Analysis Tools

This article provides a comprehensive comparison of the AD5933 integrated circuit-based impedance measurement system and traditional benchtop impedance analyzers for biomedical research and drug development applications.

AD5933 vs. Benchtop Impedance Analyzers: A Lab Scientist's Complete Guide to Biosensor & Cell Analysis Tools

Abstract

This article provides a comprehensive comparison of the AD5933 integrated circuit-based impedance measurement system and traditional benchtop impedance analyzers for biomedical research and drug development applications. We explore foundational principles, from basic impedance theory to device architectures, and detail practical methodologies for biosensing, cell monitoring, and electrochemical analysis. The guide addresses critical troubleshooting for accuracy, calibration, and noise reduction, and presents a rigorous validation framework comparing cost, precision, frequency range, and usability. Designed for researchers and scientists, this analysis clarifies when to choose a low-cost, customizable AD5933 solution versus a high-performance benchtop instrument for specific lab workflows.

Impedance Analysis 101: Core Principles, Architectures, and Key Specifications Decoded

This whitepaper elucidates the core principles of electrical impedance—resistance, capacitance, and phase—within biological contexts. It provides the theoretical foundation for evaluating the AD5933 impedance converter network against benchtop analyzers for laboratory research in biosensing, cell biology, and drug development. Accurate impedance measurements are critical for characterizing cellular morphology, adhesion, and metabolic activity in real-time, label-free assays.

Core Principles of Impedance in Biological Systems

Electrical impedance (Z) is a complex, frequency-dependent measure of opposition to current flow in a circuit or material. In biological systems, it quantifies the passive electrical properties of tissues, cell suspensions, or monolayers.

The Impedance Triangle: Resistance, Reactance, and Phase

The total impedance (Z) is a vector sum of resistance (R) and reactance (X). Resistance represents the dissipative, in-phase component, converting electrical energy to heat. Reactance (X) is the out-of-phase, energy-storing component, originating from capacitance (C) and inductance (L). In biological tissues, inductive effects are typically negligible at low frequencies (<10 MHz); thus, reactance is dominated by capacitive elements.

- Magnitude: |Z| = √(R² + Xc²)

- Phase Angle: θ = arctan(-Xc / R)

- Capacitive Reactance: Xc = -1 / (2πfC), where f is frequency.

Biological cells in suspension or adhered to electrodes can be modeled by equivalent circuits. The most common is the Randles circuit, which includes solution resistance (Rs), cell membrane capacitance (Cm), and intracellular or paracellular resistance (Rp).

Biological Origins of Impedance Components

- Resistance (R): In a typical cell-based assay using microelectrodes, the measured resistance primarily reflects ionic flow through paracellular pathways (tight junctions between adherent cells) or the conducting culture medium. An increase in cell layer confluency or barrier integrity increases the measured resistance.

- Capacitance (C): The cell membrane acts as a dielectric capacitor, separating conductive intracellular and extracellular fluids. Changes in membrane surface area, morphology, or composition alter the measured capacitance.

- Phase (θ): The phase shift between applied voltage and measured current provides critical information about the system's dominant behavior (resistive vs. capacitive) at a given frequency. It is a sensitive indicator of changes in cell state.

AD5933 vs. Benchtop Impedance Analyzers: A Technical Comparison for Lab Research

The selection between an integrated circuit like the AD5933 and a full benchtop impedance analyzer hinges on the specific requirements of the biological experiment.

Table 1: Comparative Analysis of AD5933 and Benchtop Impedance Analyzers

| Feature | AD5933-Based System | Benchtop Impedance Analyzer (e.g., Keysight E4990A, Zurich Instruments MFIA) |

|---|---|---|

| Frequency Range | Typically 1 Hz to 100 kHz (practical limits). | 1 mHz to 1 GHz+ (depending on model). |

| Impedance Range | Limited (e.g., 1 kΩ to 10 MΩ), requires calibration for specific range. | Very wide (e.g., 1 mΩ to 1 TΩ), auto-ranging. |

| Measurement Accuracy | Moderate (~0.5% typical). Highly dependent on calibration, PCB layout, and external components. | High (<0.1% typical). Stable, factory-calibrated. |

| Excitation Voltage | Fixed, typically 1.98 Vpp (programmable in on-chip DDS). | Precisely programmable (mV to V levels). |

| Data Output | Real/Imaginary or Magnitude/Phase data via I²C. | Full complex impedance, with advanced parameter extraction. |

| Key Advantage | Low cost, compact size, customizable for embedded or point-of-care systems. | High precision, accuracy, versatility, and advanced analytical software. |

| Primary Limitation | Limited performance, requires significant design effort for stable measurements. | High cost, bulky, not suitable for portable applications. |

| Ideal Use Case | Prototyping, low-cost multi-well systems, portable or long-term monitoring where ultimate precision is secondary. | Fundamental research, method validation, quality control, and measurements requiring traceable accuracy. |

Thesis Context: For a research lab, the choice is application-specific. Benchtop analyzers are superior for method development and validation, where accurate characterization of a novel bio-impedance signal is paramount. The AD5933 is advantageous for scaling up validated assays into higher-throughput, customized platforms (e.g., a 96-well plate reader built in-house) or for integrating impedance sensing into organ-on-a-chip perfusion systems.

Key Experimental Protocols for Cell-Based Impedance Assays

Protocol: Real-Time Cell Analysis (RTCA) for Monitoring Barrier Integrity

Objective: To monitor the formation and perturbation of an endothelial or epithelial cell monolayer in real-time. Materials: See "The Scientist's Toolkit" below. Methodology:

- Electrode Preparation: Sterilize the gold-film or screen-printed electrode surface (e.g., in a specialized 96-well plate) via UV irradiation for 30 minutes.

- Baseline Measurement: Add culture medium alone (100 µL/well for a 96-well format) to wells. Acquire impedance spectra (e.g., at 10 kHz single frequency or a sweep from 1 kHz to 100 kHz) using the chosen analyzer. This establishes the background (Rb).

- Cell Seeding: Seed cells at an optimized density (e.g., 50,000 cells/well for HUVECs) in complete growth medium.

- Continuous Monitoring: Place the plate in the incubator-connected station. Acquire impedance measurements at set intervals (e.g., every 15 minutes). The Cell Index (CI = (Zi - Rb) / Rb) is often calculated at a frequency sensitive to cell adhesion.

- Experimental Intervention: Once the CI plateaus (confluent monolayer, typically 24-48 hours), add the pharmacological agent (e.g., histamine for barrier disruption, a drug candidate for enhancement).

- Data Analysis: Normalize CI to the time point of intervention. A decrease in CI indicates increased paracellular flux (lower resistance) and barrier disruption.

Protocol: Single-Frequency vs. Multi-Frequency Analysis for Cell Health

Objective: To distinguish between cytotoxic (cell death) and cytostatic (cell cycle arrest) effects of a compound. Methodology:

- Baseline & Seeding: Follow steps 1-3 from Protocol 3.1.

- Control Measurement: After cells adhere (~4-8 hours), perform a full impedance spectrum sweep (e.g., 100 Hz to 100 kHz) on control wells. This "fingerprint" shows the frequency-dependent behavior of healthy cells.

- Compound Addition: Add test compounds across a range of concentrations.

- Time-Course Monitoring: Monitor at a single, low frequency (e.g., 100-400 Hz, sensitive to cell-electrode adhesion and barrier function) for rapid assessment.

- Endpoint Spectrum Analysis: At 24h and 48h, perform full spectral sweeps on all wells.

- Data Interpretation: A cytotoxic effect causes cells to detach, drastically reducing impedance at all frequencies. A cytostatic effect may show a reduced increase in low-frequency impedance (due to inhibited proliferation) but may preserve high-frequency impedance (related to membrane integrity/capacitance). The phase angle at high frequencies is particularly sensitive to membrane integrity.

Visualizing Impedance Concepts and Workflows

Electrical Impedance Vector Diagram

Cell Barrier Integrity Assay Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Bio-Impedance Experiments

| Item | Function & Application |

|---|---|

| Specialized Impedance Plates (e.g., ACEA xCelligence plates, Applied BioPhysics ECIS arrays) | Multi-well plates with integrated microelectrodes. Gold-film electrodes provide a stable, biocompatible surface for cell adhesion and long-term measurement. |

| Reference Electrodes (Ag/AgCl) | Provide a stable, known potential in the electrochemical cell, critical for accurate measurements in benchtop setups, less common in integrated 2-electrode plate systems. |

| Electrolyte Solution / Cell Culture Medium (e.g., PBS, DMEM with serum) | Conducting ionic solution necessary for current flow. Serum concentration can affect initial cell adhesion and must be kept consistent. |

| Cell Lines (e.g., HUVEC, MDCK-II, Caco-2) | Model barrier-forming or tissue-specific cells. Caco-2 cells spontaneously differentiate to form tight junctions, modeling the intestinal barrier. |

| Positive Control Reagents (e.g., Histamine, TNF-α, EGTA) | Pharmacological agents known to disrupt cell-cell junctions, validating assay sensitivity. |

| Impedance Analyzer Calibration Kits | Precision resistors and capacitors for calibrating benchtop analyzers, ensuring traceable measurement accuracy. |

| AD5933 Evaluation Board & Calibration Resistors | For prototyping systems based on the AD5933, requiring precise calibration at the specific measurement frequency and impedance range of interest. |

This whitepaper provides an in-depth technical analysis of benchtop and Integrated Circuit (IC)-based impedance analyzer architectures. The analysis is framed within a critical research thesis: evaluating the suitability of the AD5933 IC system versus traditional benchtop impedance analyzers for laboratory use in scientific research and drug development. The choice fundamentally impacts measurement accuracy, system flexibility, operational complexity, and cost, directly influencing experimental outcomes and research scalability.

Core Architectural Breakdown

Benchtop Impedance Analyzer Architecture

Benchtop analyzers (e.g., Keysight E4990A, Zurich Instruments MFIA) are self-contained, high-performance instruments. Their architecture is built around discrete, optimized subsystems:

- Signal Generation: A direct digital synthesizer (DDS) or high-stability oscillator generates a precise, programmable sine wave.

- Current-to-Voltage Conversion: A high-speed, low-noise transimpedance amplifier (TIA) converts the current from the Device Under Test (DUT) into a measurable voltage.

- Demodulation & Digitization: Sophisticated analog or digital demodulation (often using a phase-sensitive detector) extracts the in-phase (I) and quadrature (Q) components of the response signal, which are then digitized by high-resolution Analog-to-Digital Converters (ADCs).

- Processing & Control: A dedicated microprocessor or FPGA performs complex calculations (e.g., Fast Fourier Transform) to derive impedance magnitude and phase.

IC-Based System Architecture (Exemplified by AD5933)

The AD5933 is a System-on-Chip (SoC) that integrates key functions into a single package, requiring external components to form a complete system:

- On-Chip DDS: Generates an excitation frequency programmable from 1 Hz to 100 kHz.

- On-Chip ADC: A 12-bit, 1 MSPS ADC digitizes the response.

- Digital Signal Processing: An on-board DSP engine performs a Discrete Fourier Transform (DFT) on the sampled data for a single selected frequency point per measurement cycle.

- Critical External Components: Requires an external precision amplifier for current-to-voltage conversion and external calibration resistors to set the measurement range.

Quantitative Comparison Table

Table 1: Architectural & Performance Specification Comparison

| Parameter | Benchtop Analyzer (e.g., Keysight E4990A) | IC-Based System (e.g., AD5933) |

|---|---|---|

| Frequency Range | Typically 1 Hz to 120+ MHz | 1 Hz to 100 kHz |

| Impedance Range | Wide (e.g., 1 mΩ to 1 TΩ) | Limited (typically 1 kΩ to 10 MΩ), set by ext. components |

| Basic Accuracy | High (typically ~0.05% to 0.5%) | Moderate (system-dependent, ~1% to 5% typical) |

| Phase Accuracy | High (e.g., < 0.05°) | Lower (system-dependent, ~1° typical) |

| Measurement Speed | Very Fast (ms per full sweep) | Slow (ms to 100s of ms per frequency point) |

| Excitation Control | Excellent (programmable amplitude, automatic ranging) | Limited (fixed output amplitude, manual range setting) |

| System Integration | Standalone, turnkey. | Requires embedded design (PCB, microcontroller, firmware). |

| Form Factor | Large, fixed. | Highly flexible, can be miniaturized. |

| Typical Cost (Hardware) | $15,000 - $50,000+ | < $100 (IC + components) |

Table 2: Suitability for Laboratory Research Contexts

| Research Context | Recommended Architecture | Key Rationale |

|---|---|---|

| Method Development & Validation | Benchtop | Ultimate accuracy and validation capability. |

| High-Frequency Material Studies | Benchtop | Required frequency range. |

| Long-term, Stable Measurements | Benchtop | Superior temperature stability and drift performance. |

| Multi-sample, High-Throughput Screening | Context-Dependent | Benchtop for speed/accuracy; IC array for distributed, low-cost sensing. |

| In-situ, Portable, or Embedded Monitoring | IC-Based (AD5933) | Size, cost, and integration flexibility are paramount. |

| Educational & Prototyping Labs | IC-Based (AD5933) | Low cost, exposes fundamental principles. |

Experimental Protocols for Comparison

Protocol A: System Performance Benchmarking

Objective: Quantify accuracy, noise, and frequency response of an AD5933 system against a calibrated benchtop analyzer. Materials: Benchtop analyzer, AD5933 evaluation board, calibration resistors (100Ω, 1kΩ, 10kΩ, 100kΩ), precision capacitors (100pF, 10nF), breadboard, connecting cables. Methodology:

- Calibration: Perform full 2-point (open/short) or 3-point (open/short/load) calibration on the benchtop analyzer. For the AD5933, perform a gain factor calibration using a known resistor at the target frequency.

- Resistive Sweep: Measure each calibration resistor from 100 Hz to the maximum frequency of the AD5933 (100 kHz) at a fixed voltage (e.g., 200 mV). Record magnitude and phase for both systems.

- RC Network Characterization: Measure a series RC circuit (e.g., 10kΩ resistor, 10nF capacitor) across the same frequency range.

- Noise Floor Analysis: With inputs open and shorted, record the measured impedance magnitude over time at a fixed mid-range frequency (e.g., 10 kHz) to determine short-term stability and noise.

- Data Analysis: Calculate % deviation of AD5933 readings from benchtop reference. Plot Bode plots (magnitude/phase vs. frequency) for both systems.

Protocol B: Biological Application - Cell Monolayer Integrity (TEER)

Objective: Monitor Transepithelial Electrical Resistance (TEER) of a cell culture monolayer over time. Materials: Cell culture insert, electrodes, cell culture media, incubator, benchtop analyzer, AD5933-based custom system with electrode interface. Methodology:

- Setup: Seed cells on permeable insert membrane. Place electrodes in apical and basolateral chambers.

- Benchtop Measurement: At each time point, remove insert, place in measurement station, and measure impedance at a single low frequency (e.g., 10-100 Hz) using the benchtop analyzer. Return to incubator.

- IC-Based In-situ Measurement: Use a miniaturized, sterilizable AD5933 system integrated into the incubator or culture plate lid. Program it to measure at the same frequency automatically at set intervals.

- Comparison: Compare the TEER trend curves from both systems, noting any discrepancies caused by moving the culture for benchtop measurement versus in-situ stability.

Visualization Diagrams

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Impedance-Based Experiments

| Item | Function in Experiment |

|---|---|

| Precision Calibration Resistors (e.g., 0.1% tolerance) | Provides known reference impedance for system calibration and validation of measurement accuracy. |

| Low-ESR Capacitors & Inductors | Used to construct known RC/LC networks for testing analyzer frequency response and phase accuracy. |

| Electrode Systems (e.g., Ag/AgCl, gold, IDEs) | Transduce ionic current in biological/chemical samples into measurable electronic current. Choice depends on application and frequency. |

| Electrolyte Solutions (e.g., PBS, KCl) | Standardized ionic media for electrochemical cell measurements, ensuring consistent and reproducible conditions. |

| Cell Culture Inserts (e.g., Transwell) | Permeable supports for growing cell monolayers used in TEER measurements for barrier function studies. |

| Faraday Cage / Shielded Enclosure | Minimizes external electromagnetic interference (EMI), crucial for low-current and high-impedance measurements. |

| Low-Noise, Shielded Cables & Connectors | Preserves signal integrity by reducing capacitive pickup and cable-induced artifacts, especially at higher frequencies. |

| Temperature Control Chamber | Maintains constant sample temperature, as impedance of materials and biological samples is highly temperature-sensitive. |

This technical guide provides an in-depth analysis of the AD5933, a precision impedance converter system-on-chip, within the research context of evaluating its suitability as an alternative to benchtop impedance analyzers in laboratory settings, particularly for drug development and biomedical research. The assessment focuses on core operational principles, key capabilities, and practical implementation against the benchmark of traditional benchtop instruments.

The primary thesis framing this analysis is: "Determining the viability of the AD5933 integrated circuit as a cost-effective, space-efficient, and sufficiently accurate alternative to traditional benchtop impedance analyzers for specific, well-defined laboratory applications in research and drug development." This evaluation is critical for labs seeking to decentralize testing, create portable assays, or reduce capital equipment costs without sacrificing essential data integrity for lower-frequency impedance measurements.

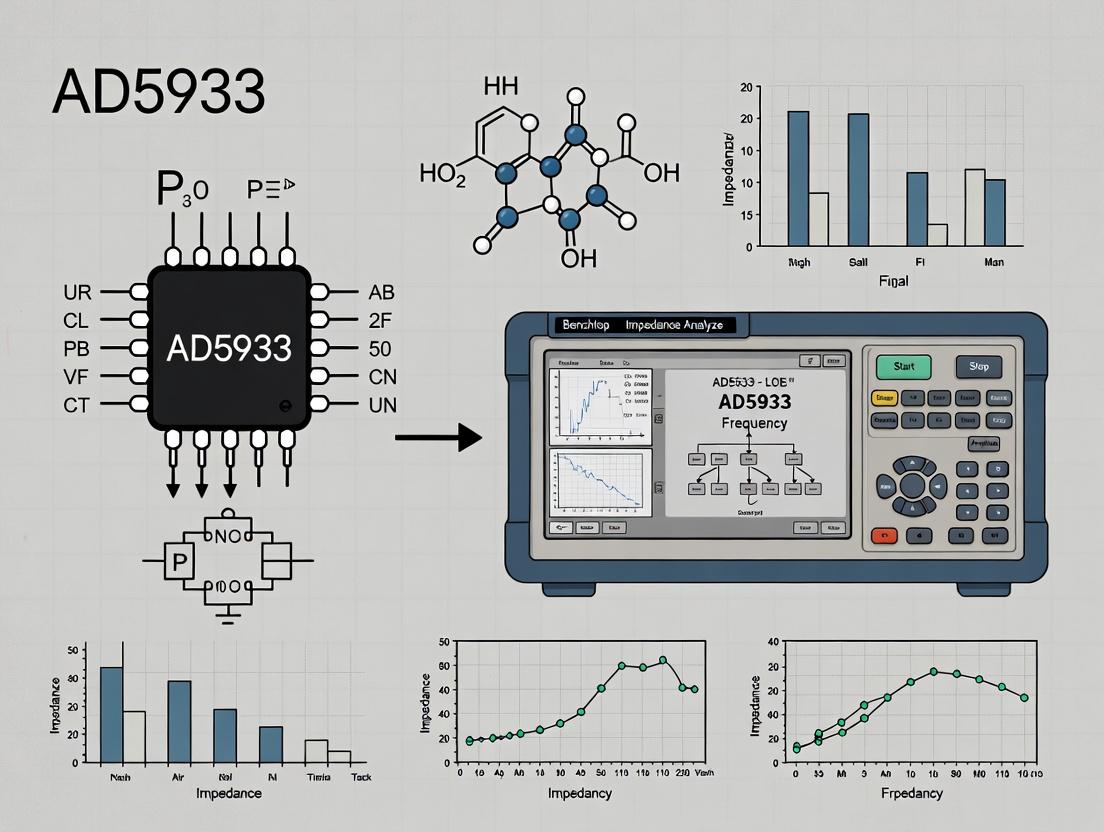

How the AD5933 Works: System Architecture

The AD5933 is a complex mixed-signal device that performs a discrete frequency sweep to measure impedance. Its operation can be broken down into a core signal chain and digital control pathway.

Core Signal Chain and Digital Control

Diagram Title: AD5933 Impedance Measurement Signal Flow

Process Workflow:

- Frequency Generation: A Direct Digital Synthesizer (DDS) core generates a precise digital sine wave representation based on user-programmed start frequency, increment, and number of points.

- Excitation: The digital waveform is converted to an analog voltage (VOUT) by the on-board 12-bit DAC. This signal excites the unknown impedance (Z) connected in series with a known current-sensing feedback resistor (R_FB).

- Signal Conditioning: The resulting current through the network creates a voltage across R_FB, which is amplified by the Programmable Gain Amplifier (PGA).

- Digitization and Analysis: The conditioned signal is digitized by a 12-bit ADC. The digital samples are processed by an on-chip Discrete Fourier Transform (DFT) engine at the excitation frequency.

- Output: The DFT outputs the in-phase (Real) and quadrature (Imaginary) components of the response. An external microcontroller computes the complex impedance using calibration data.

Critical Calibration Workflow

Accurate measurement requires a two-point calibration against a known calibration resistor.

Diagram Title: AD5933 Two-Point Calibration Protocol

Core Capabilities: Quantitative Specifications vs. Benchtop Analyzers

Table 1: AD5933 vs. Typical Benchtop Impedance Analyzer Specifications

| Parameter | AD5933 (On-a-Chip) | Typical Benchtop Analyzer (e.g., Keysight E4990A) | Implication for Research |

|---|---|---|---|

| Frequency Range | 1 Hz to 100 kHz | 1 Hz to 3 GHz (Wideband) | AD5933 suitable for electrochemical, biosensor, material characterization at low frequencies. Benchtop required for RF components or high-speed kinetics. |

| Impedance Range | 1 kΩ to 10 MΩ (optimal with R_FB selection) | 1 mΩ to 1 TΩ (with multiple ranges) | Benchtop offers vastly broader range. AD5933 requires careful matching of R_FB to expected Z, limiting dynamic range in a single setup. |

| Measurement Accuracy | ±0.5% typical (after calibration, at optimal Z) | ±0.05% to ±0.1% typical | Benchtop provides higher precision critical for detecting subtle changes (e.g., small molecule binding). AD5933 adequate for larger-scale effects. |

| Output Excitation | 1.98 Vp-p max, fixed waveform (sine) | Variable amplitude (mV to V), arbitrary waveforms | Benchtop allows optimization for sensitive samples (low voltage) or nonlinear materials. AD5933 is less flexible. |

| Data Throughput | ~30 ms per frequency point (typical) | < 1 ms per point (high speed) | Benchtop superior for high-resolution sweeps or time-series monitoring of fast processes. |

| Form Factor & Cost | ~$30 (IC), PCB-based system | $20,000 - $100,000+ | AD5933 enables multiplexed, portable, or embedded systems at a fraction of the cost. |

| Interface & Control | I²C Digital Interface | GPIB, LAN, USB, extensive front-panel | AD5933 is software-driven, ideal for integration into automated, custom lab setups. Benchtop offers standalone usability. |

Table 2: AD5933 System-Level Performance Summary

| Characteristic | Specification / Value | Notes for Experimental Design |

|---|---|---|

| Frequency Resolution | 27-bit DDS (0.1 Hz at 100 kHz clock) | Allows fine-grained sweeps for detailed dispersion analysis. |

| Clock Source | Onboard 16.776 MHz oscillator or external | External clock recommended for precise frequency generation and system synchronization. |

| Power Supply | 2.7 V to 5.5 V, ~20 mA active | Enables battery-powered and portable measurement systems. |

| Temperature Range | -40°C to +85°C (industrial) | Suitable for environmental chambers or non-climate-controlled lab spaces. |

| Key Limitation | Single-ended, grounded measurement | Not suitable for floating or fully differential measurements without external circuitry. |

Experimental Protocols for Key Applications

Protocol: Characterizing a Biosensor in a Microfluidic Well

Objective: Monitor the change in electrochemical impedance of a functionalized electrode surface upon protein binding in real-time at a single frequency.

The Scientist's Toolkit:

| Research Reagent / Material | Function in Experiment |

|---|---|

| AD5933 Evaluation Board | Provides the core measurement hardware with accessible terminals. |

| Custom PDMS Microfluidic Cell | Houses the biosensor electrode and controls fluidic delivery of samples. |

| Gold Working Electrode | Functionalized surface for biomolecule immobilization. |

| Phosphate Buffered Saline (PBS) | Provides a consistent ionic strength and pH for biochemical reactions. |

| Target Protein Solution | The analyte of interest which binds to the sensor surface. |

| Blocking Agent (e.g., BSA) | Used to passivate non-specific binding sites on the sensor. |

| Precision Feedback Resistor (R_FB) | Selected (e.g., 10 kΩ) to match the expected sensor impedance (10-100 kΩ). |

| Calibration Resistor Set | Precision resistors (e.g., 10kΩ, 100kΩ) for initial system calibration. |

| Microcontroller (e.g., Arduino, PSoC) | Programs the AD5933 and streams data to a PC for analysis. |

Methodology:

- System Setup: Connect the biosensor working electrode to VOUT and the counter electrode to the R_FB/input node. Place the cell in PBS.

- Calibration: Replace the sensor with a precision 10 kΩ resistor. Perform a sweep from 100 Hz to 10 kHz to determine the system's Gain Factor (GF) at the target monitoring frequency (e.g., 1 kHz).

- Baseline Measurement: Reconnect the sensor. Flow PBS to stabilize. Measure and record the impedance magnitude and phase at 1 kHz every 5 seconds for 5 minutes to establish a stable baseline (Z_baseline).

- Introduce Analyte: Switch flow to the target protein solution. Continue monitoring impedance at the same interval for 15-30 minutes.

- Data Analysis: Calculate the normalized impedance change ΔZ/Z = (Z(t) - Zbaseline) / Zbaseline. Plot ΔZ/Z vs. time to obtain a binding kinetic curve.

Protocol: Multi-Frequency Sweep of Battery Electrode Material

Objective: Obtain a Nyquist plot of a lithium-ion coin cell half-cell to estimate charge-transfer resistance and Warburg diffusion element.

Methodology:

- Cell Connection: Connect the AD5933 system to a coin cell test fixture. A potentiostat circuit may be required to bias the cell at its open-circuit voltage.

- Sweep Configuration: Program a logarithmic frequency sweep from 10 kHz down to 1 Hz with 10 points per decade.

- Calibration: Perform calibration with a resistor close to the expected cell impedance (e.g., 100 Ω) at multiple spot frequencies across the band.

- Measurement: Execute the sweep, collecting real (R) and imaginary (I) data at each frequency.

- Model Fitting: Plot -Imaginary vs. Real (Nyquist plot). Fit the curve to an equivalent circuit model (e.g., Randles circuit) using software like ZView to extract parameters like solution resistance (Rs), charge-transfer resistance (Rct), and double-layer capacitance (C_dl).

Within the defined thesis, the AD5933 presents a compelling alternative to benchtop analyzers for low-frequency (≤100 kHz), moderate-accuracy, and cost- or space-sensitive applications. Its core capability lies in transforming complex analog measurement into a digital system integration problem. For drug development, this enables high-throughput, multiplexed impedance-based assays (e.g., for cell monitoring or immunosensing) at a dramatically lower per-station cost. However, for research requiring the highest accuracy, ultra-wide impedance or frequency ranges, or advanced analysis features (like built-in equivalent circuit fitting), a traditional benchtop impedance analyzer remains indispensable. The choice is not one of outright replacement but of strategic tool selection based on specific research requirements and constraints.

In the context of academic and industrial lab research, selecting the appropriate impedance measurement tool involves a critical evaluation of performance specifications against practical needs. This whitepaper, framed within a broader thesis comparing the integrated circuit AD5933 to traditional benchtop impedance analyzers, provides a detailed technical guide for researchers and development professionals in fields like biosensing and drug development.

Core Specification Analysis

The choice between a compact solution like the AD5933 and a full benchtop analyzer hinges on four interdependent key specifications.

1. Frequency Range This defines the spectrum of alternating current (AC) test frequencies an instrument can generate and measure. It determines the type of information that can be extracted, as biological systems and materials exhibit frequency-dependent impedance.

- AD5933: Operates within a limited range, typically 1 Hz to 100 kHz (dependent on external clock and system design). This covers the β-dispersion region relevant for many cell-based assays, where cellular membrane properties and intracellular conductivity are probed.

- Benchtop Analyzers (e.g., Keysight, Zurich Instruments): Offer vastly broader ranges, from µHz to GHz. This enables the study of very slow electrochemical processes (µHz) and very fast dielectric relaxations or material properties (MHz-GHz).

2. Accuracy Accuracy quantifies how close a measurement result is to the true impedance value. It is affected by systematic errors, calibration quality, and inherent circuit limitations.

- AD5933: Moderate accuracy, typically around 5-10% of reading for a well-calibrated system. Accuracy is highly dependent on a stable, known calibration resistor close to the unknown impedance value and is best within a limited impedance magnitude range (e.g., 1 kΩ to 1 MΩ).

- Benchtop Analyzers: High accuracy, often 0.1% or better of reading. They incorporate advanced auto-calibration routines, error compensation models (open/short/load), and sophisticated electronics to minimize systematic errors across a wide impedance and frequency span.

3. Resolution Resolution is the smallest change in impedance magnitude or phase that the instrument can detect and display. It is crucial for monitoring subtle, real-time changes in biological samples.

- AD5933: Resolution is fundamentally limited by its 12-bit analog-to-digital converter (ADC) for the response signal and the stability of its on-board oscillator. Phase resolution is particularly limited.

- Benchtop Analyzers: Feature high-resolution (e.g., 24-bit) ADCs and precision signal sources, enabling detection of minute changes in both magnitude and phase angle.

4. Measurement Speed Speed refers to how quickly a single impedance measurement or a frequency sweep can be completed. This is critical for high-throughput screening or kinetic studies.

- AD5933: Offers relatively fast single-frequency point measurements (milliseconds). However, sweeping across many frequencies involves software-controlled steps and settling time delays, slowing full sweeps.

- Benchtop Analyzers: Extremely fast, leveraging dedicated hardware processors for real-time analysis. Can perform high-speed sweeps or continuous monitoring at thousands of points per second.

Quantitative Data Comparison

The table below summarizes typical specification ranges for the AD5933 system and a representative mid-range benchtop impedance analyzer.

| Specification | AD5933-Based System | Representative Benchtop Analyzer (e.g., Keysight E4990A) |

|---|---|---|

| Frequency Range | 1 Hz – 100 kHz | 10 µHz – 120 MHz |

| Basic Accuracy | ~5% (Magnitude, system-dependent) | 0.08% (Magnitude) |

| Impedance Range | ~100 Ω to 10 MΩ (optimal) | 1 mΩ to 1 TΩ |

| Measurement Resolution | 12-bit ADC (limited phase resolution) | 24-bit ADC, 0.01° phase resolution |

| Sweep Speed | Moderate (software-controlled settling) | Very Fast (<1 ms per point in fast mode) |

| Key Advantage | Low cost, portability, integration | High accuracy, speed, broad frequency range |

Experimental Protocols for Validation

To quantitatively compare these platforms in a lab research context, the following experimental methodologies can be employed.

Protocol 1: Stability and Accuracy Assessment Using Calibrated Passive Components

- Objective: Determine baseline accuracy and drift over time.

- Materials: Precision resistors (e.g., 1kΩ, 10kΩ, 100kΩ ±0.1%), calibrated reference capacitors.

- Method:

- Connect a 10kΩ precision resistor to the measurement terminals.

- For the AD5933, perform a system calibration at 1 kHz using a calibration resistor matching the unknown's expected value.

- For the benchtop analyzer, perform a full open/short/load calibration at the measurement plane.

- Measure the impedance magnitude and phase at 1 kHz every 60 seconds for 60 minutes under controlled temperature.

- Repeat for multiple frequencies (100 Hz, 10 kHz) and different component values.

- Data Analysis: Calculate mean measured value, standard deviation, and % error from the known nominal value. Plot drift over time.

Protocol 2: Characterizing a Biological Model System (e.g., Electrolyte Solution)

- Objective: Evaluate performance in a realistic, low-impedance research scenario.

- Materials: Potassium chloride (KCl) solutions (e.g., 0.1M, 0.01M), two-electrode or four-electrode electrochemical cell.

- Method:

- Prepare KCl solutions with known conductivity.

- Fill the electrochemical cell and connect to the analyzer.

- For the benchtop unit, use a dedicated conductivity fixture or a four-terminal pair connection for optimal accuracy.

- For the AD5933, implement a suitable front-end circuit for electrode interfacing.

- Perform a frequency sweep from 100 Hz to 100 kHz.

- Record the impedance spectrum.

- Data Analysis: Fit the obtained spectrum to an equivalent circuit model (e.g., a solution resistance in series with a constant phase element for the electrode interface). Compare the extracted solution resistance (and thus calculated conductivity) to the expected value.

Protocol 3: Kinetic Monitoring of a Dynamic Process

- Objective: Assess measurement speed and resolution for time-sensitive applications.

- Materials: A slowly hydrating polymer film or a model redox couple solution (e.g., Ferri/Ferrocyanide).

- Method:

- Initialize the measurement at a single, optimal frequency (e.g., the frequency of maximum phase change for the system).

- Trigger the dynamic process (e.g., add solvent, apply a voltage step).

- Record impedance magnitude and phase in continuous time-lapse mode.

- Configure the benchtop analyzer for its highest measurement speed setting.

- Configure the AD5933 for continuous polling of its output registers.

- Data Analysis: Plot impedance parameters vs. time. Compare the temporal resolution (data points per second) and the signal-to-noise ratio of the captured transient.

Visualizing the Decision Workflow

Decision Flow: Selecting an Impedance Measurement Tool

AD5933 System Architecture & Data Flow

The Scientist's Toolkit: Key Research Reagent Solutions

The table below lists essential materials for impedance-based research, particularly in bio-applications.

| Item | Function in Impedance Research |

|---|---|

| Phosphate-Buffered Saline (PBS) | Standard electrolyte solution for maintaining physiological ionic strength and pH in cell-based assays. Provides a stable baseline impedance. |

| Tetrapolar Electrochemical Cell | A cell with four electrodes: two for current injection, two for voltage sensing. Mitigates electrode polarization effects for accurate solution conductivity measurement. |

| Interdigitated Electrode (IDE) Array | Microfabricated sensor with interlaced fingers. Provides high sensitivity for surface binding events and localized electric fields for cell monitoring. |

| Calibrated Precision Resistors | High-accuracy (±0.1% or better) resistors used as known references for system calibration and validation of instrument accuracy. |

| Faraday Cage | A shielded enclosure that blocks external electromagnetic fields, reducing environmental noise for low-current, high-impedance measurements. |

| Equivalent Circuit Modeling Software | Software (e.g., ZView, EC-Lab) used to fit experimental impedance spectra to theoretical circuit models, extracting physiochemical parameters. |

This technical guide explores the core applications of impedance analysis in biomedical laboratories, framed within the context of evaluating the viability of the integrated circuit-based AD5933 impedance analyzer versus traditional benchtop impedance analyzers for research purposes.

Impedance analysis is a cornerstone technique in biomedical research, enabling non-invasive, label-free, and real-time monitoring of biophysical properties. The choice between a low-cost, portable system like the AD5933 and a high-performance benchtop analyzer hinges on the specific requirements of precision, frequency range, and analytical complexity for each primary use case.

Impedance Analyzers: AD5933 vs. Benchtop Systems

A comparative analysis is essential for researchers selecting an appropriate tool.

Table 1: Specifications Comparison: AD5933 vs. Typical Benchtop Analyzer

| Parameter | AD5933-Based System | Benchtop Impedance Analyzer (e.g., Keysight E4990A) |

|---|---|---|

| Frequency Range | 1 Hz to 100 kHz | 1 mHz to 3 / 30 / 120 MHz (model dependent) |

| Impedance Range | ~1 kΩ to 10 MΩ (circuit dependent) | Wide range, e.g., 1 mΩ to 1 TΩ |

| Measurement Accuracy | Moderate (0.5% typical, heavily circuit/calib. dependent) | High (0.05% to 0.1% typical) |

| Cost | Low (Component cost < $50) | High ($20,000 - $100,000+) |

| Portability | Excellent (can be embedded) | Poor (rack-mounted or large desktop unit) |

| Ease of Use & Software | Requires custom firmware/UI development | Comprehensive, vendor-supported software |

| Primary Advantage | Cost, portability, customization for a single task | Accuracy, reliability, broad frequency & impedance range |

| Ideal Use Context | Dedicated, narrow-range monitoring systems | R&D, characterization, multi-application labs |

Core Laboratory Use Cases & Experimental Protocols

Electrode Characterization and Functionalization

Objective: To quantify the interfacial properties of biosensor electrodes (e.g., gold, ITO, carbon) before and after surface modification (e.g., with self-assembled monolayers or capture antibodies).

Protocol:

- Setup: Place the bare electrode in a controlled electrolyte (e.g., 1x PBS or 5 mM K₃[Fe(CN)₆]/K₄[Fe(CN)₆]).

- Measurement: Perform an electrochemical impedance spectroscopy (EIS) sweep (e.g., 0.1 Hz to 100 kHz) at the open circuit potential with a small AC perturbation (10 mV).

- Functionalization: Chemically modify the electrode surface (e.g., incubate in 1 mM thiol solution for 2 hours).

- Post-Modification Measurement: Repeat the EIS sweep in the same electrolyte.

- Analysis: Fit Nyquist plots to an equivalent circuit model (e.g., Randles circuit with a constant phase element) to extract parameters like charge transfer resistance (Rct) and double-layer capacitance (Cdl), which indicate modification success.

Table 2: Electrode Characterization Results Example

| Electrode State | Rct (kΩ) | Cdl (nF) | Notes |

|---|---|---|---|

| Bare Gold | 1.2 ± 0.2 | 120 ± 15 | Low barrier to redox probe electron transfer. |

| SAM-Modified | 45.3 ± 5.1 | 18 ± 3 | High Rct confirms successful insulating monolayer formation. |

| Antibody-Coated | 68.7 ± 7.5 | 15 ± 2 | Further increase confirms protein binding. |

Toolkit Applicability: Benchtop analyzers provide superior resolution for detailed interfacial studies. The AD5933 can be used for basic quality control of electrode batches within its frequency limits.

Cell Culture Monitoring (e.g., Electric Cell-Substrate Impedance Sensing - ECIS)

Objective: To monitor in real-time cell proliferation, morphology changes, and barrier function (in endothelial or epithelial layers) non-invasively.

Protocol:

- Seeding: Seed cells onto a specialized cultureware containing integrated microelectrodes.

- Baseline: Measure impedance (often at multiple frequencies, e.g., 400 Hz, 2 kHz, 10 kHz) immediately after seeding in media.

- Continuous Monitoring: Place the cultureware in a standard incubator connected to an impedance monitoring system. Take readings every 1-15 minutes.

- Perturbation (Optional): Introduce a compound (drug, toxin) and monitor the impedance response over time.

- Analysis: Track impedance magnitude or the derived parameter "normalized cell index." Low frequencies are sensitive to cell number and barrier function, while higher frequencies are more sensitive to cell morphology.

Toolkit Applicability: AD5933-based systems are ideal for creating custom, multi-well, real-time monitoring setups at a fraction of the cost of commercial ECIS instruments, though with less precision. Benchtop analyzers are used for foundational research and developing new assay models.

Diagram 1: ECIS Impedance Response to Cell Coverage

Biomolecular Sensing and Diagnostic Assays

Objective: To detect the presence and concentration of a target analyte (DNA, protein, pathogen) via impedance change upon binding on a functionalized electrode.

Protocol (Sandwich Immunoassay Example):

- Capture: Immobilize capture antibodies on the electrode surface.

- Blocking: Apply a blocking agent (e.g., BSA) to prevent non-specific binding.

- Baseline Measurement: Record impedance in buffer.

- Incubation: Introduce the sample containing the target antigen. Incubate, then wash.

- Secondary Binding: Introduce a labeled detection antibody. Incubate, then wash.

- Signal Generation (if labeled): If using an enzyme label (e.g., HRP), add a substrate that generates an insoluble precipitate on the electrode, dramatically increasing Rct.

- Final Measurement: Record impedance. The change in Rct (ΔRct) correlates with analyte concentration.

Toolkit Applicability: The AD5933 excels in developing low-cost, point-of-care diagnostic prototypes. Benchtop analyzers are critical for assay development, optimization, and characterizing binding kinetics with high resolution.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Impedance-Based Bioassays

| Item | Function / Role in Experiment |

|---|---|

| Interdigitated Electrode (IDE) Chips | Standardized microelectrodes for consistent electric field generation, used in ECIS and biosensing. |

| Redox Probe (e.g., [Fe(CN)₆]³⁻/⁴⁻) | Provides a measurable electron transfer pathway; changes in its efficiency indicate surface modifications or blocking events. |

| Thiolated Molecules (e.g., 11-MUA) | Form self-assembled monolayers (SAMs) on gold electrodes, providing a stable, functionalizable surface for biomolecule attachment. |

| NHS/EDC Crosslinker Kit | Activates carboxyl groups on SAMs or surfaces for covalent coupling of proteins (antibodies, peptides). |

| Blocking Agents (BSA, Casein) | Minimize non-specific adsorption of proteins to the sensor surface, improving assay specificity and signal-to-noise ratio. |

| Specific Antibody Pairs (Capture/Detection) | Form the core of immunoassays, providing high specificity for the target antigen. |

| Cell Culture Media & Supplements | Maintain cell viability and normal physiology during long-term impedance monitoring experiments. |

| Trypsin-EDTA Solution | Detaches adherent cells from surfaces, used for standardizing cell seeding densities in ECIS experiments. |

The selection between an AD5933-based system and a benchtop impedance analyzer is not a matter of superiority, but of appropriate application. For high-precision characterization, method development, and work requiring wide frequency ranges, benchtop analyzers remain indispensable. For developing dedicated, cost-effective, and portable monitoring systems for specific tasks like cell culture health or point-of-care diagnostics, the AD5933 offers a powerful, flexible alternative that can democratize access to impedance-based techniques in biomedical labs.

Hands-On Protocols: Implementing AD5933 and Benchtop Analyzers for Biosensing & Cell Studies

This guide provides an in-depth technical framework for electrode setup, a critical and often overlooked variable in comparative impedance analysis studies. The methodologies herein are framed within a broader research thesis evaluating the performance of the integrated circuit-based AD5933 impedance converter against traditional benchtop impedance analyzers (e.g., Keysight, Zurich Instruments) for laboratory use in bio-impedance applications, such as monitoring cell culture or biomolecular interactions in drug development. Consistent, well-designed measurement setup is paramount for generating valid comparative data between these two classes of instruments.

Core Principles of Electrode Design for Bio-Impedance

The electrode is the transducer between the electrical measurement system and the ionic conductive sample. Its design dictates the current distribution, sensitivity, and signal-to-noise ratio.

Two-Electrode vs. Three/Four-Electrode Configurations:

- Two-Electrode: Each electrode serves as both current-injecting and voltage-sensing. Simple but susceptible to errors from electrode polarization impedance, especially at low frequencies. More suitable for the AD5933 in basic configurations.

- Three/Four-Electrode: Separate current-injecting and voltage-sensing electrodes. The sensing electrodes measure the voltage drop in the sample with minimal current flow, effectively negating the polarization impedance at the sensing interface. Essential for accurate, low-frequency measurements and the preferred method for benchtop analyzers.

Material Selection: Choice affects conductivity, polarizability, and biocompatibility.

- Geometry and Surface Area: Determines current density and the interface impedance. Consistent geometry is critical for reproducibility.

Quantitative Comparison: AD5933 vs. Benchtop Analyzer Requirements

The system choice imposes different constraints and optimizations on the setup design.

Table 1: Electrode & Fixturing Requirements by System

| Parameter | AD5933-Based System | Benchtop Impedance Analyzer | Rationale & Impact |

|---|---|---|---|

| Optimal Electrode Config | Primarily 2-Electrode. 4-Electrode possible with external circuitry. | Native support for 2, 3, and 4-Electrode configurations. | AD5933's on-chip signal chain is designed for a simple unknown impedance between two nodes. Benchtop units have separate, isolated meters. |

| Excitation Voltage | Typically fixed (e.g., 1.98 Vpp). Limited programmability. | Widely programmable (mV to V range). | AD5933's fixed voltage can drive significant current in low-Z samples, causing nonlinearity or sample damage. Benchtop allows optimization for sensitivity and sample health. |

| Frequency Range | 1 Hz - 100 kHz (typical with accurate clock source). | 1 mHz - 10+ MHz. | Electrode polarization is severe at low frequencies (<100 Hz). A 4-electrode setup is often necessary for AD5933 to access its lower range accurately. |

| Input Impedance | ~10 MΩ on VIN pin. | >1 GΩ (on voltage sensing channels). | Lower input impedance on AD5933 can cause signal loading in high-Z measurements, requiring buffer amplifiers for reliable cell culture monitoring. |

| Fixturing Needs | Critical. Requires custom PCB or shielded fixture for stable connections. | Standardized coaxial cables (e.g., BNC, SMA) to probe stations. | AD5933 is sensitive to stray capacitance; benchtop analyzers use active guarding and sophisticated cable compensation routines. |

Experimental Protocols for Comparative Studies

Protocol 4.1: Characterizing Electrode Polarization Impedance

Objective: Quantify the contribution of the electrode-electrolyte interface to the total measured impedance. Materials: Test electrolyte (e.g., 0.1M PBS), electrode pair, measurement system (AD5933 fixture and benchtop analyzer). Method:

- Fabricate electrode pairs with identical material but different surface areas (e.g., 0.5 cm² and 0.25 cm²).

- Immerse both pairs in the same PBS bath under identical conditions.

- Using a benchtop analyzer in a 2-electrode mode, perform an impedance sweep from 1 Hz to 100 kHz.

- Fit the resulting spectra to an equivalent circuit model (e.g., a series resistor with a constant phase element (CPE) for the interface). The CPE parameters model the polarization.

- Repeat with the AD5933 system. Compare the extracted parameters, noting the frequency range where polarization dominates (>50% of phase shift).

Protocol 4.2: Validating a 4-Electrode Adapter for AD5933

Objective: Implement a 4-electrode measurement using the AD5933 to reduce polarization error. Materials: AD5933 evaluation board, dual current-feedback op-amp (e.g., AD811), precision instrumentation amplifier (e.g., INA128), passive components, four identical electrodes. Method:

- Build Circuit: Construct the circuit as per the diagram below. The current source drives the outer electrodes (C1, C2). The voltage sense amplifier measures the differential potential between the inner electrodes (P1, P2).

- Calibrate: Use precision resistors (100Ω, 1kΩ, 10kΩ) placed at the sample position to calibrate the AD5933 system. The calibration must account for the gain of the external amplifiers.

- Validate: Measure the impedance of a standardized electrolyte (known conductivity) across a range of frequencies. Compare results against a benchtop analyzer in 4-terminal mode.

Diagram 1: 4-Electrode System for AD5933 (60 chars)

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for Impedance Biosensor Setup

| Item | Function & Relevance | Example/Specification |

|---|---|---|

| Gold Planar Electrodes | Low chemical reactivity, easily functionalized for biosensing. Standard for cell culture substrates. | 250 nm Au on 10 nm Ti adhesion layer on glass slide. |

| Ag/AgCl Pellets | Reversible, non-polarizable electrode. Essential for stable reference potential in 3/4-electrode setups. | BASi brand, filled with 3M KCl electrolyte gel. |

| Phosphate Buffered Saline (PBS) | Standard physiologically conductive medium for baseline testing and calibration. | 0.01M, pH 7.4, sterile filtered. |

| Cell Culture Media | Conductive growth medium for in vitro experiments. Impedance changes indicate cell adhesion/proliferation. | DMEM with 10% FBS, phenol-red free for optical clarity. |

| ECIS Electrode Arrays | Commercial, standardized 8-well slides with interdigitated electrodes for high-throughput cell monitoring. | Applied BioPhysics, 10W10E+ models. |

| Conductive Silver Epoxy | For making reliable, low-resistance connections between electrode substrates and wires. | Epoxy Technology, H20E. |

| Faraday Cage | Enclosure to shield sensitive, high-impedance measurements (esp. AD5933) from ambient EM noise. | DIY with grounded aluminum mesh or sheet. |

Fixturing and Connection Best Practices

- Shielding and Guarding: Enclose the AD5933 circuit and electrode leads in a grounded metallic enclosure (Faraday cage). Use guard traces on PCBs to reduce parasitic capacitance.

- Cable Management: Use short, rigid connections. For benchtop analyzers, always perform open/short/load compensation at the exact point where the sample connects.

- Sample Chamber: Ensure geometric stability. Use O-rings or gaskets to define a consistent electrode area and sample volume. Temperature control is highly recommended.

- Connection Sequence: Always connect the ground/shield first, then the signal lines, before applying power or excitation to the sample.

Diagram 2: Measurement Setup Decision Workflow (76 chars)

This guide provides a detailed configuration protocol for the Analog Devices AD5933 impedance converter system, framed within a broader research thesis comparing its performance against traditional benchtop impedance analyzers for laboratory use. The thesis hypothesis posits that while benchtop analyzers (e.g., Keysight E4990A, Zurich Instruments MFIA) offer superior accuracy and frequency range, a properly configured AD5933 system provides a cost-effective, customizable, and "good-enough" solution for specific, repetitive lab measurements in fields like drug development and biosensing.

Core System Components & Quantitative Comparison

Table 1: AD5933 System vs. Benchtop Analyzer Key Specifications

| Parameter | AD5933-Based System | Typical Benchtop Analyzer (e.g., Keysight E4990A) | Implication for Lab Use |

|---|---|---|---|

| Frequency Range | 1 Hz to 100 kHz | 1 Hz to 3 GHz | AD5933 suitable for bio-impedance (≤100 kHz). |

| Impedance Range | 1 kΩ to 10 MΩ (with front-end) | 1 mΩ to 1 TΩ | AD5933 requires front-end design for specific range. |

| Accuracy (Typical) | 0.5% to 5% (system dependent) | 0.05% to 0.1% | Benchtop superior for absolute measurements. |

| Excitation Voltage | Programmable, typ. 0.2 to 2 V p-p | Programmable, up to ±20 V | AD5933 limited for high-impedance materials. |

| Measurement Speed | ~30 ms per point (system dependent) | ~1-10 ms per point | Comparable for low-point-count sweeps. |

| Cost | ~$50-$500 (components) | $15,000 - $50,000+ | AD5933 enables high accessibility. |

| Customization | High (open firmware, front-end) | Low (closed, vendor-defined) | AD5933 allows application-specific optimization. |

Step-by-Step Configuration Protocol

Hardware Configuration

A. Microcontroller Interface

- MCU Selection: Use an MCU with a robust I²C interface and sufficient GPIO. Common choices include:

- Arduino Uno/Nano (ATmega328P): For simplicity and prototyping.

- STM32 Nucleo (ARM Cortex-M): For higher performance and DMA.

- Raspberry Pi Pico (RP2040): For dual-core processing and custom PIO.

- Wiring Protocol:

- Connect AD5933

VDDto +3.3V. DO NOT USE 5V. - Connect

GNDto common ground. - Connect

SCLandSDAto MCU I²C pins with 4.7 kΩ pull-up resistors to 3.3V. - Connect

MCLKto an MCU-generated square wave (2.5-5 MHz) for the internal system clock.

- Connect AD5933

B. Front-End (Analog) Design The critical stage for lab-ready measurements. A basic transimpedance amplifier (TIA) is required.

Table 2: Essential Research Reagent Solutions & Materials (The Scientist's Toolkit)

| Item | Function in AD5933 Experiment | Typical Example / Specification |

|---|---|---|

| AD5933 Evaluation Board | Quick-start platform for initial validation. | Analog Devices EVAL-AD5933EBZ. |

| Precision Op-Amp | Core of the front-end TIA; determines bandwidth and noise. | OPA2188 (low noise, low offset). |

| Calibration Resistor Kit | Set of high-precision, low-inductance resistors for system calibration. | 1 kΩ, 10 kΩ, 100 kΩ, 1 MΩ, 0.1% tolerance. |

| Electrochemical Cell or DUT Fixture | Holds the Device Under Test (DUT). | Custom PCB with Kelvin clips or a glass cell with gold electrodes. |

| Low-EMF Cabling | Minimizes noise in low-signal measurements. | Shielded coaxial or twisted-pair cables. |

| Buffer Solution (e.g., PBS) | For biosensor measurements, provides stable ionic environment. | 1X Phosphate Buffered Saline, pH 7.4. |

| Reference Electrolyte | For electrochemical impedance spectroscopy (EIS) validation. | 5 mM Potassium Ferricyanide in 1M KCl. |

| Stable Voltage Regulator | Provides clean 3.3V and 5V rails to analog and digital components. | LT3042 (low noise LDO). |

Experimental Protocol 1: TIA Front-End Assembly & Calibration

- Assemble Circuit: Build a TIA using a precision op-amp. Connect the AD5933's

VOUTto the TIA input via a current-limiting resistor (~100Ω). The DUT connects between TIA input and virtual ground. - Calibrate Gain Resistor (

Rfb):- Replace DUT with a precision calibration resistor (

Rcal). - Run an impedance sweep. The AD5933 returns a complex value (real

R, imaginaryI). - Calculate gain factor:

GF = 1 / (Rcal * sqrt(R² + I²)). StoreGFfor this frequency. - Repeat for all frequencies in the sweep to create a frequency-dependent

GFarray.

- Replace DUT with a precision calibration resistor (

- Validate: Measure a known resistor (different value from

Rcal). Calculate impedance:Z = 1 / (GF * sqrt(R² + I²)). Accuracy should be within <1% error for the mid-impedance range.

Title: AD5933 Front-End Signal Path & Calibration Switching

Software & Firmware Configuration

Experimental Protocol 2: Microcontroller Firmware Setup

- Initialize I²C & Clock: Configure MCU's I²C at 400 kHz. Generate a stable

MCLK(e.g., 4 MHz) using a timer or PLL. - AD5933 Register Setup (Key Steps):

- Reset: Write to Control Register (0x80).

- Set Start Frequency: Write 3 bytes to registers 0x82, 0x83, 0x84.

f_start = (freq_word * MCLK) / 2^27. - Set Frequency Increment: Registers 0x85, 0x86, 0x87.

- Set Number of Increments: Registers 0x88, 0x89.

- Set Output Voltage & PGA: Register 0x80. Example:

0x11for 2.0 V p-p, PGA gain x1.

- Measurement Loop:

- Issue Start Frequency Sweep command (0x10).

- Poll Status Register (0x8F) for Valid Data bit.

- Read Real and Imaginary data registers (0x94-0x97).

- Apply calibration data (

GF) to calculate impedance. - Issue Increment Frequency command, repeat.

Title: AD5933 System Firmware Workflow Logic

System Validation Experiment

Experimental Protocol 3: Comparative Performance Analysis (AD5933 vs. Benchtop)

- Objective: Quantify accuracy and noise performance of the configured AD5933 system against a reference benchtop analyzer.

- Materials: Configured AD5933 system, Keysight E4990A, calibration resistor kit, RC network board (100Ω + 100nF).

- Method:

- Resistor Sweep: Measure impedance magnitude (|Z|) and phase (θ) of resistors (1kΩ, 10kΩ, 100kΩ) from 100 Hz to 50 kHz using both systems.

- RC Network Sweep: Measure the series RC network across the same range to assess frequency response.

- Noise Floor: Short the DUT terminals and measure the standard deviation of |Z| over 100 readings at 1 kHz.

- Data Analysis: Calculate percent error relative to the benchtop analyzer's value or the component's nominal value. Plot Bode plots (|Z| and θ vs. f) for both systems.

Table 3: Example Validation Results (Hypothetical Data)

| DUT | Frequency | Benchtop | Z | (Ω) | AD5933 | Z | (Ω) | Error (%) | Benchtop Phase (°) | AD5933 Phase (°) | Phase Error (°) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10.00 kΩ Resistor | 1 kHz | 10000.5 | 10015.2 | +0.15% | -0.01 | -0.5 | -0.49 | ||||

| 100.0 kΩ Resistor | 10 kHz | 100001 | 98650 | -1.35% | -0.02 | -1.8 | -1.78 | ||||

| 100Ω + 100nF RC | 5 kHz | 361.2 | 358.9 | -0.64% | -56.31 | -55.1 | +1.21 | ||||

| Noise Floor (Short) | 1 kHz | 0.05 Ω (std dev) | 2.1 Ω (std dev) | N/A | N/A | N/A | N/A |

This guide provides a replicable protocol for configuring a lab-ready AD5933 measurement system. The validation data demonstrates that while a well-configured AD5933 system can achieve sub-2% error for mid-range impedances near its calibration point, it exhibits higher noise and phase error compared to a benchtop analyzer. This supports the thesis that the AD5933 is a viable, low-cost tool for specific lab applications where absolute precision is secondary to relative changes (e.g., sensor kinetics, cell growth monitoring). However, for characterization of novel materials or validation of sensors requiring traceable accuracy, a benchtop impedance analyzer remains the indispensable laboratory standard.

This Standard Operating Procedure (SOP) provides a comprehensive guide for operating a modern benchtop impedance analyzer, detailing each step from initialization to data export. The protocol is framed within a research thesis comparing integrated circuit solutions like the AD5933 with full-featured benchtop analyzers for laboratory use in biosensing and material characterization. While IC-based systems offer portability and cost benefits, benchtop analyzers provide superior accuracy, measurement flexibility, and advanced analytical software, making them indispensable for critical research and drug development applications where data integrity is paramount.

Safety & Pre-Operational Checklist

2.1 Personal Protective Equipment (PPE): Wear appropriate lab coat, safety glasses, and nitrile gloves. 2.2 Workspace: Ensure a stable, vibration-free benchtop. Verify power source (100-240 VAC, 50/60 Hz) and proper grounding. 2.3 Analyzer Inspection: Check for visible damage to the unit, front-panel connectors, and test leads. 2.4 Calibration Status: Confirm the instrument's calibration is current per the lab's quality control schedule.

Detailed Step-by-Step Operating Procedure

System Warm-up & Initialization

- Power On: Press the main power switch on the rear panel. Allow the instrument to boot completely.

- Stabilization Period: Let the analyzer warm up for a minimum of 60 minutes to ensure thermal stability of internal oscillators and circuitry. This is critical for achieving specified accuracy.

- Initial State: After warm-up, press the

Localkey on the front panel to ensure remote operation (if used) is disabled.

Test Setup & Cable Connection

- Fixture Selection: Choose the appropriate test fixture (e.g., 2-terminal, 4-terminal pair, or a dedicated electrode fixture) for your Device Under Test (DUT).

- Connection: Securely connect the fixture cables to the analyzer's designated

HIGHandLOWcurrent and potential ports. For 4-terminal measurements, ensureHIGHandLOWpotential leads are connected inside the current leads on the DUT. - DUT Mounting: Place or connect the DUT (e.g., a sensor in a flow cell, a battery cell, a material sample) to the fixture. Ensure secure, stable contacts.

Basic Measurement Configuration

Access the MEASURE menu and configure the core parameters as detailed in Table 1.

Table 1: Core Measurement Parameter Configuration

| Parameter | Typical Setting | Purpose & Notes | ||

|---|---|---|---|---|

| Measurement Function | Impedance ( | Z | and θ) | Core output. May also select admittance (Y). |

| Frequency Range | User-defined (e.g., 1 Hz – 1 MHz) | Sets start (Fstart) and stop (Fstop) frequencies. | ||

| Number of Points | 10 per decade (or 101 points logarithmic) | Determines measurement resolution. | ||

| AC Signal Level | 10 mV (for electrochemical cells) | Applied test voltage. Must be within DUT's linear range. | ||

| DC Bias | 0 V (unless specified) | Superimposed DC potential. | ||

| Averaging Factor | 3 to 5 | Reduces random noise at the cost of speed. | ||

| Integration Time / Bandwidth | Medium (or 3 Hz) | Sets measurement speed/accuracy trade-off. |

Advanced Setup: Equivalent Circuit Analysis

For in-situ analysis, configure the analyzer's built-in model fitting:

- Navigate to

ANALYSIS>EQUIVALENT CIRCUIT. - Select a predefined model (e.g.,

R_s + (C_dl || R_ct)for a simple electrode-electrolyte interface). - Initiate the fitting routine. The analyzer will output fitted parameter values (e.g., Rct, Cdl).

Measurement Execution & Data Validation

- Open/Short/Load Compensation: Perform this correction after fixture connection but before DUT measurement.

- Measure known

OPEN,SHORT, and standardLOAD(e.g., 1 kΩ resistor) conditions. - The analyzer stores error terms (stray capacitance, lead inductance, residual impedance) to correct subsequent DUT data.

- Measure known

- Run Measurement: Press

SingleorRunto initiate the frequency sweep. - Real-Time Monitor: Observe the Nyquist (Cole-Cole) or Bode plots on screen for obvious anomalies (e.g., open circuit arcs, excessive scatter).

Data Export Protocol

- Storage: Save the data file to the instrument's internal memory or a connected USB drive.

- Export Format: Select multi-column ASCII text (

.txtor.csv) for maximum compatibility with external software (e.g., ZView, Origin, Python). - Data Structure: Ensure the exported file includes at minimum: Frequency (Hz), |Z| (Ω), Phase (θ, degrees), Zreal (Ω), Zimag (Ω).

- Transfer: For networked instruments, use SCPI commands or vendor software to transfer data directly to a laboratory server.

Experimental Protocol: Impedance-Based Monitoring of Cell Barrier Integrity

This protocol, frequently cited in drug development, highlights the analyzer's application.

Objective: To monitor the formation and perturbation of a monolayer of Madin-Darby Canine Kidney (MDCK) cells cultured on a porous membrane using a benchtop analyzer.

Materials: See "The Scientist's Toolkit" below. Method:

- Setup: Insert the cell culture-transwell insert with electrodes into the customized holder connected to the analyzer.

- Baseline: Measure the impedance spectrum (e.g., 100 Hz to 100 kHz) of the cell-free coated membrane in culture medium. Record as Day 0 control.

- Monitoring: Seed cells on the membrane. Perform a brief, low-resolution impedance measurement (e.g., at a single representative frequency like 400 Hz or 1 kHz) daily to track monolayer growth without stressing the cells.

- Full Characterization: On days of interest (e.g., pre-confluent, confluent, post-treatment), perform a full multi-frequency sweep.

- Perturbation Experiment: At confluence, add a compound under investigation (e.g., a candidate drug, an inflammatory cytokine). Measure impedance at the single frequency every 5-15 minutes and full spectra at baseline and endpoint.

- Data Analysis: Calculate the Normalized Cell Index or Transendothelial Electrical Resistance (TEER) using the analyzer's math function:

R_cell = R_total - R_blank, where R is derived from the real component of impedance at the selected frequency.

Diagram Title: Workflow for Impedance-Based Cell Barrier Assay

Benchtop Analyzer vs. AD5933: Key Performance Data

Table 2: Comparative Analysis of Benchtop Analyzer vs. AD5933 IC Solution

| Feature | Benchtop Analyzer (e.g., Keysight E4990A) | AD5933-Based System | Impact on Research |

|---|---|---|---|

| Frequency Range | 1 Hz to 3/10/30/120 MHz (model dependent) | 1 kHz to 100 kHz | Benchtop enables dielectric spectroscopy & wide dispersion analysis. |

| Impedance Range | 1 mΩ to 100 MΩ (extended with fixtures) | ~1 kΩ to 10 MΩ | Benchtop handles batteries (low Z) and insulators (high Z). |

| Basic Accuracy | ±0.05% to ±0.8% typical | ~5% to 10% (system dependent) | Critical for quantitative model fitting and publication. |

| Excitation Control | Precisely variable AC voltage/current, DC bias | Fixed AC voltage range, no DC bias | Benchtop allows linearity checks and electrochemistry. |

| Built-in Analysis | Full equivalent circuit fitting, graphing | Raw impedance & phase data only | Drastically reduces post-processing time for researchers. |

| Automation | Full SCPI command set, LAN/GPIB/USB | Limited I2C commands for data fetch | Benchtop integrates into automated high-throughput workflows. |

The Scientist's Toolkit: Key Reagent Solutions & Materials

Table 3: Essential Materials for Impedance-Based Cellular Assays

| Item | Function & Rationale |

|---|---|

| Cell Culture-Transwell Inserts | Polyester/Collagen-coated porous membranes (0.4-3.0 µm pores) that serve as the scaffold for cell growth and are compatible with electrode integration. |

| Gold-plated or ITO Electrodes | Provide stable, biocompatible, and low-impedance electrical interfaces for transepithelial/transendothelial measurements. |

| Cell Culture Medium | Standard growth medium (e.g., DMEM + FBS) for maintaining cell viability during experiments. Phenol-red free medium is recommended for optical clarity if combining with microscopy. |

| Trypsin-EDTA Solution | For detaching and passaging cells prior to seeding on inserts. |

| Paracellular Tracer Molecules | (e.g., Fluorescein isothiocyanate–dextran) Used in parallel experiments to validate impedance data with a direct measure of permeability. |

| Positive Control Compounds | (e.g., Histamine, EGTA, TNF-α) Known disruptors of barrier function used to calibrate assay sensitivity and instrument response. |

| Electrode Cleaning Solution | (e.g., 70% ethanol, Hellmanex solution) For decontamination and removal of protein/biofilm buildup from electrodes between experiments. |

Diagram Title: Key Components in a Cell Barrier Impedance Assay

Routine Maintenance & Shutdown

- Daily: Power down the analyzer after use if not in frequent service. Disconnect test fixtures and store them properly.

- Weekly: Clean the instrument's exterior and cooling vents with a soft, dry cloth.

- Monthly: Perform a basic verification using a known precision resistor (e.g., 1 kΩ ±0.01%).

- Annual/As Recommended: Schedule professional calibration and performance verification with the manufacturer or certified metrology lab.

Troubleshooting Guide

- Noisy/Erratic Data: Check cable connections, increase averaging, reduce AC signal level, ensure DUT stability, verify proper warm-up.

- Impedance Out of Expected Range: Verify open/short/load compensation was performed, check for poor DUT contact, confirm fixture compatibility.

- Communication Error with PC: Verify cable/port settings, check instrument is in

REMOTEmode, reinstall/update driver software.

This SOP, when followed meticulously, ensures the generation of high-fidelity impedance data. Within the thesis context, it underscores that while the AD5933 serves well for dedicated, narrow-range applications, the benchtop impedance analyzer remains the gold standard for rigorous, flexible, and publication-ready research in pharmaceutical development and advanced materials science.

Abstract: This whitepaper provides an in-depth technical examination of Transendothelial/Epithelial Electrical Resistance (TEER) as the gold standard for real-time, non-destructive monitoring of cell layer integrity. Framed within a broader research thesis comparing the utility of the integrated circuit AD5933 impedance analyzer against traditional benchtop systems for laboratory research, this guide details protocols, data analysis, and practical implementation strategies for researchers in drug development and basic biology.

In modern cell biology and drug development, real-time quantification of cell layer health and barrier function is paramount. TEER measurement is a critical technique for assessing the formation and breakdown of tight junctions in endothelial and epithelial monolayers (e.g., blood-brain barrier, intestinal lining). The core instrument for this is an impedance analyzer.

The research thesis central to this discussion posits that while traditional benchtop impedance analyzers offer high precision and broad frequency ranges, compact, lower-cost solutions centered on chips like the Analog Devices AD5933 can provide sufficient accuracy, greater accessibility, and superior integration potential for long-term, automated culture monitoring. This guide explores TEER implementation through both paradigms.

Core Principles of TEER Measurement

TEER quantifies the ionic flow resistance across a confluent cell layer cultured on a porous membrane insert. As tight junctions form, resistance increases; upon insult (e.g., cytotoxic compounds, inflammatory cytokines), resistance drops. The measured resistance (Ω) is normalized by the membrane's surface area (cm²) to calculate TEER (Ω·cm²).

- Key Formula:

TEER (Ω·cm²) = (R_total - R_blank) × Effective Membrane AreaR_total: Measured resistance of cell layer + membrane + medium.R_blank: Resistance of blank membrane + medium (background).- Effective Membrane Area: Area of the porous membrane (e.g., 0.33 cm² for common 24-well inserts).

System Comparison: AD5933 vs. Benchtop Analyzer

The table below summarizes the quantitative comparison central to the overarching thesis.

Table 1: Technical Comparison of TEER Measurement Systems

| Feature | Benchtop Impedance Analyzer (e.g., Keysight, Zurich Instruments) | AD5933-Based Custom System |

|---|---|---|

| Typical Frequency Range | 1 Hz – 50+ MHz | 1 Hz – 100 kHz |

| Impedance Accuracy | High (±0.1% typical) | Moderate (±5% typical, depends on calibration) |

| Measurement Channels | Typically 1-2, expandable with multiplexers at high cost | Easily scalable to multi-well arrays via multiplexing ICs |

| Cost per Channel | Very High ($5k - $20k+) | Very Low ($10 - $50 per channel for core electronics) |

| Integration Potential | Stand-alone unit, limited by proprietary software. | High. Can be integrated into incubators, controlled via Arduino/Raspberry Pi. |

| Primary Research Use Case | High-precision, single-experiment characterization; broad-spectrum EIS. | Long-term, real-time kinetic studies; high-throughput screening; custom bioreactor integration. |

| Key Advantage | Ultimate precision, stability, and support. | Accessibility, scalability, and customization for kinetic monitoring. |

Experimental Protocols

Protocol 1: Standardized TEER Measurement for Barrier Integrity Assessment

Objective: To monitor the formation and cytokine-induced disruption of a Caco-2 intestinal epithelial monolayer.

Materials (Scientist's Toolkit): Table 2: Essential Research Reagent Solutions for TEER Assays

| Item | Function & Explanation |

|---|---|

| Caco-2 Cells | Human colorectal adenocarcinoma cell line; gold standard for intestinal barrier models. |

| DMEM, High Glucose | Culture medium providing essential nutrients for cell growth. |

| Fetal Bovine Serum (FBS) | Serum supplement providing growth factors and adhesion proteins. |

| Transwell Polyester/Collagen Inserts | Permeable supports with defined pore size (e.g., 0.4 μm) for cell polarization. |

| TNF-α & IL-1β Cytokines | Pro-inflammatory cytokines used to experimentally induce barrier dysfunction. |

| EVOM2 or CellZScope (Benchmark) | Commercial benchtop TEER meters for validation of custom system data. |

| Sterile Electrodes (Ag/AgCl) | Non-cytotoxic electrodes for reliable, stable measurements. |

| Custom AD5933 Board w/ MUX | For scalable, real-time data acquisition (core thesis component). |

Methodology:

- Cell Seeding: Seed Caco-2 cells at high density (e.g., 1x10^5 cells/cm²) onto collagen-coated Transwell inserts. Place inserts in a 24-well plate with medium in both apical and basolateral chambers.

- Monitoring Growth: Measure TEER daily using either a benchtop system (for periodic checks) or a continuously measuring AD5933 array placed inside the incubator.

- Experimental Insult: Once TEER plateaus (typically >300 Ω·cm²), add a cocktail of TNF-α (10 ng/mL) and IL-1β (5 ng/mL) to the basolateral chamber.

- Kinetic Measurement: Record TEER every 15-30 minutes for 24-48 hours using the AD5933 system. Validate key timepoints with a benchtop meter.

- Data Normalization: Subtract the average resistance of blank inserts from all values. Multiply by the insert's effective membrane area. Plot as TEER (Ω·cm²) vs. Time.

Protocol 2: System Calibration for AD5933-based Measurement

Objective: To ensure accurate impedance readings from a custom AD5933 circuit.

Methodology:

- Circuit Setup: Implement a 4-terminal (2-probe) connection to the cell culture insert. Include a multiplexer for multi-well reading.

- Calibration with Known Resistors: Over the expected measurement range (e.g., 50Ω to 2kΩ), measure a series of precision resistors (1% tolerance) in the measurement fixture.

- Gain Factor Calculation: Use the AD5933's internal calibration routine to compute a gain factor for each frequency point of interest (typically a single low frequency, e.g., 100 Hz - 10 kHz for TEER).

- Validation with RC Network: Measure a known resistor-capacitor parallel network to verify phase and magnitude accuracy across the frequency sweep.

Signaling Pathways in Barrier Dysfunction

Inflammatory cytokine-induced TEER reduction is mediated through defined intracellular signaling pathways.

Diagram 1: Cytokine-Induced Barrier Disruption Signaling

Experimental Workflow for Comparative Thesis Research

The logical flow for a study validating an AD5933 system against a benchtop analyzer.

Diagram 2: Thesis Validation Workflow

Real-time TEER monitoring is indispensable for barrier function research. Benchtop analyzers provide reference-standard data, validating the AD5933's capability to deliver reliable, kinetically rich data at a fraction of the cost and with superior scalability. For longitudinal studies, high-throughput screens, and customized microenvironment integration, an AD5933-based system presents a compelling, research-grade alternative, shifting the thesis from pure performance comparison to one of optimal tool application.

This technical guide explores the application of electrochemical impedance spectroscopy (EIS) in biosensor development, specifically framed within a comparative research context: employing a cost-effective, integrated impedance analyzer like the AD5933 versus a traditional benchtop impedance analyzer for laboratory research. The primary thesis investigates whether the AD5933, with its limitations in frequency range and precision, can yield sufficiently reliable data for the characterization of electrochemical biosensors, particularly in proof-of-concept and early-stage development phases where accessibility and cost are constraints. The target is to define the suitability envelope for each tool.

Core Principles of Electrochemical Biosensors

Electrochemical biosensors transduce a biological recognition event (e.g., antibody-antigen binding, DNA hybridization, enzymatic reaction) into a quantifiable electrical signal. EIS is a powerful, non-destructive technique for characterizing the step-by-step fabrication of these sensors and for monitoring biomolecular interactions in real-time. It measures the complex impedance (Z) of an electrochemical cell as a function of frequency.